BS 6346 PVC Insulated Cables, 600/1000V

Multi-core 600/1000V cables with stranded copper conductors

APPLICATION

These power and control cables are used for electricity supply in low voltage installation system. They are well adapted to underground use in industrial applications where chemical and mechanical protections are needed (refinery areas, chemical plant...).

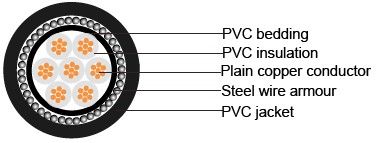

CONSTRUCTION

| Conductor | Solid Aluminum or Copper conductor, round stranded or shaped, Class 2 to BS 6460, IEC 60228. |

| Insulation | PVC(Polyvinyl Chloride) type TI1 |

| Colour Code | 1 Core : Brown |

| 2 Cores : Brown or Blue | |

| 3 Cores : Brown, Black, Grey | |

| 4 Cores : Blue, Brown, Black, Grey | |

| 5 Cores : Green-yellow, Blue, Brown, Black, Grey | |

| Above 5 Cores : White Cores with black numbers | |

| Filler(optional) | PVC or Polypropylene yarn |

| Binder Tape(optional) | Polyester (Mylar) tape |

| Inner Sheath/Bedding | PVC (Polyvinyl Chloride) |

| Armour | Single Core : AWA (Aluminum Wire Armour) |

| Multi Core : SWA (Steel Wire or Tape Armour) | |

| Outer Sheath | PVC(Polyvinyl Chloride), type TM1 |

TECHNICAL INFORMATION

| Voltage rating | 600/1000V |

| Temperature rating | -20°C to +60°C |

| Bending radius | Single core : 10 x overall diameter |

| Multicores : 8 x overall diameter | |

| Flame retardant | IEC60332 part 1, BS4066 part 1 |

CABLE PARAMETER

| No. of Cores | Nominal cross- sectional area | Number/wire | Nominal insulation thickness | Nomina l bedding thick- ness | Nominal alum wire armor dia. | Nominal sheath thick- ness | Approx. overall diameter | Approx. cable weight |

| mm² | No./mm | mm | mm | mm | mm | mm | kg/mm | |

| 7 | 1.5 | 7/0.53 | 0.6 | 0.8 | 0.9 | 1.4 | 15.2 | 500 |

| 10 | 1.5 | 7/0.53 | 0.6 | 0.8 | 1.25 | 1.5 | 18.6 | 780 |

| 12 | 1.5 | 7/0.53 | 0.6 | 0.8 | 1.25 | 1.5 | 19.4 | 830 |

| 19 | 1.5 | 7/0.53 | 0.6 | 0.8 | 1.25 | 1.6 | 22.2 | 1090 |

| 27 | 1.5 | 7/0.53 | 0.6 | 1.0 | 1.6 | 1.7 | 26.7 | 1600 |

| 37 | 1.5 | 7/0.53 | 0.6 | 1.0 | 1.6 | 1.8 | 29.2 | 1940 |

| 48 | 1.5 | 7/0.53 | 0.6 | 1.0 | 1.6 | 1.9 | 32.9 | 2360 |

| 7 | 2.5 | 7/0.67 | 0.7 | 0.8 | 1.25 | 1.5 | 18.0 | 750 |

| 10 | 2.5 | 7/0.67 | 0.7 | 0.8 | 1.25 | 1.6 | 21.8 | 1000 |

| 12 | 2.5 | 7/0.67 | 0.7 | 0.8 | 1.25 | 1.6 | 22.4 | 1080 |

| 19 | 2.5 | 7/0.67 | 0.7 | 1.0 | 1.6 | 1.7 | 26.6 | 1640 |

| 27 | 2.5 | 7/0.67 | 0.7 | 1.0 | 1.6 | 1.8 | 30.7 | 2110 |

| 37 | 2.5 | 7/0.67 | 0.7 | 1.0 | 1.6 | 1.9 | 34.0 | 2600 |

| 48 | 2.5 | 7/0.67 | 0.7 | 1.2 | 2.0 | 2.1 | 39.5 | 3520 |

| 7 | 4 | 7/0.85 | 0.8 | 0.8 | 1.25 | 1.6 | 20.5 | 970 |

| 10 | 4 | 7/0.85 | 0.8 | 1.0 | 1.6 | 1.7 | 26.1 | 1500 |

| 12 | 4 | 7/0.85 | 0.8 | 1.0 | 1.6 | 1.7 | 26.8 | 1630 |

| 19 | 4 | 7/0.85 | 0.8 | 1.0 | 1.6 | 1.8 | 30.5 | 2170 |

| 27 | 4 | 7/0.85 | 0.8 | 1.2 | 2.0 | 2.0 | 37.1 | 3170 |

| 37 | 4 | 7/0.85 | 0.8 | 1.2 | 2.0 | 2.1 | 40.8 | 3910 |

| 48 | 4 | 7/0.85 | 0.8 | 1.2 | 2.0 | 2.2 | 46.0 | 4790 |