PAS 5308 Cable Part 2 Type 1 PVC-IS-OS-PVC

Applications

PAS 5308 Cable Part 2 Type 1 PVC-IS-OS-PVC are designed to connect electrical instrumentation and communication systems in and around process plants and similar applications, Generally used to transmit analogue or digital signals in measurement and process control where chemicals may be present. The individual screening of each pair limits the consequence of crosstalk.

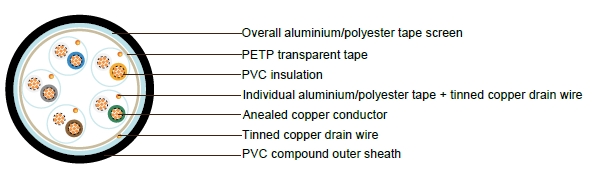

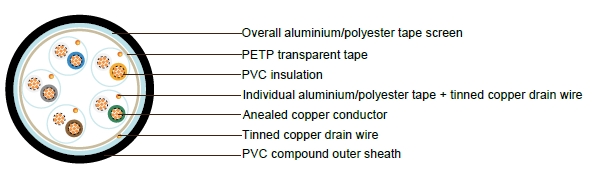

Construction

| Conductor |

Annealed copper, sizes: 0.5mm^2 mulitistranded(Class 5), 0.5 mm^2 and 1.0 mm^2 solid(Class 1), 1.5mm^2 or 2.5 multistranded(Class 2) to BS EN 60228 |

| Insulation |

PVC to BS EN 50290-2-21:2002, grade TI51 |

| Pairing |

Two insulated conductors uniformly twisted together with a lay not exceeding 100mm, Two-pair cables without individual pair screens (quads) shall have four cores laid in quad formation round a central dummy |

| Colour code |

See technical information |

| Individual screen |

Aluminium/polyester tape is applied over each pair metallic side down in contact with tinned copper drain wire, 0.5mm^2 |

| Binder tape |

Non-hygroscopic binder tape of minimum thickness 0.023 mm |

| Collective screen |

Aluminium/polyester tape is applied over the laid up pairs metallic side down in contact with tinned copper drain wire, 0.5mm^2 |

| Outer sheath |

Extruded sheath of a PVC compound conforming to BS EN 50290-2-22:2002, grade TM51 |

| Sheath colour |

Generally black |

Electrical Properties

| Temperature range |

above 0C( fixed installation) |

| |

-15C to +65C(during operation ) |

| Conductor Area Size |

mm^2 |

0.5 |

0.5 |

1.0 |

1.5 |

2.5 |

| Conductor Stranding |

No. x mm |

1 x 0.8 |

16 x 0.2 |

1 x 1.13 |

7 x 0.53 |

7 x 0.67 |

| Conductor resistance max |

ohm/km |

36.8 |

39.7 |

18.4 |

12.3 |

7.6 |

| Insulation resistance min |

Individual conductor |

Gohm/km |

5 |

5 |

5 |

5 |

5 |

| |

individual screen |

Mohm/km |

1 |

1 |

1 |

|

1 |

| Capacitance unbalance at 1kHz(pair to pair screen) |

pF/250m |

250 |

| Max. Mutual Capacitance @ 1kHz for Non OS or OS cables (except one-pair and two-pairs) |

pF/m |

75 |

75 |

75 |

85 |

105 |

| Max. Mutual Capacitance @ 1kHz IS/OS cables (include 1 pairand 2 pair) |

pF/m |

115 |

115 |

115 |

120 |

140 |

| Max. L/R Ratio for adjacentcores(Inductance/Resistance) |

μH/ohm |

25 |

25 |

25 |

40 |

60 |

| Test voltage |

V |

2000 |

2000 |

2000 |

2000 |

2000 |

| Rated voltage |

V |

300/500 |

300/500 |

300/500 |

300/500 |

300/500 |

Parameter

| Number of Pairs |

Number and Diameter of Wires |

Nominal Conductor Cross-Sectional Area |

Nominal Thickness of Insulation |

Nominal Thickness of Sheath |

Nominal Diameter of Cable |

| no./mm |

mm^2 |

mm |

mm |

mm |

stranded conductor 0.5 mm^2 (16/0.20mm) |

| 2 |

16/0.2 |

0.5 |

0.6 |

0.9 |

9.7 |

| 5 |

16/0.2 |

0.5 |

0.6 |

1 |

12.6 |

| 10 |

16/0.2 |

0.5 |

0.6 |

1.2 |

18 |

| 15 |

16/0.2 |

0.5 |

0.6 |

1.3 |

20.9 |

| 20 |

16/0.2 |

0.5 |

0.6 |

1.4 |

23.6 |

| 30 |

16/0.2 |

0.5 |

0.6 |

1.6 |

28.2 |

| 50 |

16/0.2 |

0.5 |

0.6 |

1.8 |

36.1 |

stranded conductor 0.75 mm^2 (24/0.20mm) |

| 2 |

24/0.2 |

0.75 |

0.6 |

0.9 |

10.4 |

| 5 |

24/0.2 |

0.75 |

0.6 |

1 |

13.5 |

| 10 |

24/0.2 |

0.75 |

0.6 |

1.2 |

19.4 |

| 15 |

24/0.2 |

0.75 |

0.6 |

1.4 |

22.8 |

| 20 |

24/0.2 |

0.75 |

0.6 |

1.5 |

25.8 |

| 30 |

24/0.2 |

0.75 |

0.6 |

1.6 |

30.5 |

| 50 |

24/0.2 |

0.75 |

0.6 |

1.9 |

39.3 |

stranded conductor 1.5 mm^2 (7/0.53mm) |

| 2 |

7/0.53 |

1.5 |

0.6 |

1 |

12.1 |

| 5 |

7/0.53 |

1.5 |

0.6 |

1.1 |

15.8 |

| 10 |

7/0.53 |

1.5 |

0.6 |

1.4 |

22.9 |

| 15 |

7/0.53 |

1.5 |

0.6 |

1.5 |

26.6 |

| 20 |

7/0.53 |

1.5 |

0.6 |

1.6 |

30.1 |

| 30 |

7/0.53 |

1.5 |

0.6 |

1.8 |

35.8 |

| 50 |

7/0.53 |

1.5 |

0.6 |

2.2 |

46.2 |

stranded conductor 2.5 mm^2 (7/0.67mm) |

| 2 |

7/0.67 |

2.5 |

0.6 |

1 |

13.5 |

| 5 |

7/0.67 |

2.5 |

0.6 |

1.2 |

17.9 |

| 10 |

7/0.67 |

2.5 |

0.6 |

1.5 |

25.9 |

| 15 |

7/0.67 |

2.5 |

0.6 |

1.6 |

30.1 |

| 20 |

7/0.67 |

2.5 |

0.6 |

1.8 |

34.3 |

| 30 |

7/0.67 |

2.5 |

0.6 |

2 |

40.8 |

| 50 |

7/0.67 |

2.5 |

0.6 |

2.4 |

52.6 |