Windmill Cables

H07BN4-F 450/750V Torsion Resistant Cable

Application

These cables with increased tolerance to torsion application, improved behaviour against abrasion and extended temperature, UV and ozone resistant are specially designed for wind turbines and to be used for the loop.

Standards

DIN VDE 0282.12

HD 22.12

Construction

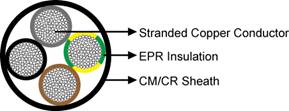

Conductor: Stranded bare copper,class 5 according to DIN VDE 0295/HD 383/ IEC 60228.

Insulation: Cold and heat resistant EPR. Special cross-linked EI7 rubber for high temperatures can be offered upon request.

Sheath: Ozone, UV-resistant, oil and cold-resistant special compound based on CM (chlorinated polyethylene)/CR (chloroprene rubber). Special cross-linked EM7 rubber can be offered upon request.

Technical Data

Rated Voltage U0/U (Um) |

450/750V |

Operating Temperatures |

-40℃~+90℃ |

Minimum Bending Radius |

6×OD |

Maximum Permissible Tensile Load |

15 N/mm² |

Torsion Application |

+/-150°/m |

Short-circuit Temperature |

250℃ |

Flame Retardant |

EN 50265-1/EN 50265-2-1/IEC 60332-1 |

Oil Resistant |

Yes |

Ozone Resistant |

Yes |

UV Resistant |

Yes |

Dimensions and Weight

Construction |

Nominal Overall Diameter |

Nominal Weight |

No. of cores×mm² |

mm |

kg/km |

1×25 |

13.5 |

371 |

1×35 |

15.0 |

482 |

1×50 |

17.3 |

667 |

1×70 |

19.3 |

888 |

1×95 |

22.7 |

1160 |

1×(G)10 |

28.6 |

175 |

1×(G)16 |

28.6 |

245 |

1×(G)25 |

28.6 |

365 |

1×(G)35 |

28.6 |

470 |

1×(G)50 |

17.9 |

662 |

1×(G)70 |

28.6 |

880 |

1×(G)120 |

24.7 |

1430 |

1×(G)150 |

27.1 |

1740 |

1×(G)185 |

29.5 |

2160 |

1×(G)240 |

32.8 |

2730 |

1×300 |

36.0 |

3480 |

1×400 |

40.2 |

4510 |

10G1.5 |

19.0 |

470 |

12G1.5 |

19.3 |

500 |

12G2.5 |

22.6 |

670 |

18G1.5 |

22.6 |

725 |

18G2.5 |

26.5 |

980 |

2×1.5 |

28.6 |

110 |

2×2.5 |

28.6 |

160 |

2×4 |

12.9 |

235 |

2×6 |

14.1 |

275 |

2×10 |

19.4 |

530 |

2×16 |

21.9 |

730 |

2×25 |

26.2 |

1060 |

24G1.5 |

26.4 |

980 |

24G2.5 |

31.4 |

1390 |

3×25 |

28.6 |

1345 |

3×35 |

32.2 |

1760 |

3×50 |

37.3 |

2390 |

3×70 |

43.0 |

3110 |

3×95 |

47.2 |

4170 |

3×(G)1.5 |

10.1 |

130 |

3×(G)2.5 |

12.0 |

195 |

3×(G)4 |

13.9 |

285 |

3×(G)6 |

15.6 |

340 |

3×(G)10 |

21.1 |

650 |

3×(G)16 |

23.9 |

910 |

3×120 |

51.7 |

5060 |

3×150 |

57.0 |

6190 |

4G1.5 |

11.2 |

160 |

4G2.5 |

13.6 |

240 |

4G4 |

15.5 |

350 |

4G6 |

17.1 |

440 |

4G10 |

23.5 |

810 |

4G16 |

25.9 |

1150 |

4G25 |

31.0 |

1700 |

4G35 |

35.3 |

2170 |

4G50 |

40.5 |

3030 |

4G70 |

46.4 |

3990 |

4G95 |

52.2 |

5360 |

4G120 |

56.5 |

6480 |

5G1.5 |

12.2 |

230 |

5G2.5 |

14.7 |

295 |

5G4 |

17.1 |

430 |

5G6 |

19.0 |

540 |

5G10 |

25.0 |

1020 |

5G16 |

28.7 |

1350 |

5G25 |

35.0 |

2080 |

5G35 |

38.4 |

2650 |

5G50 |

43.9 |

3750 |

5G70 |

50.5 |

4950 |

5G95 |

57.8 |

6700 |

6G1.5 |

14.7 |

295 |

6G2.5 |

16.9 |

390 |

7G1.5 |

16.5 |

350 |

7G2.5 |

18.5 |

460 |

8×1.5 |

17.0 |

400 |