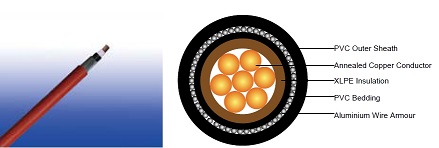

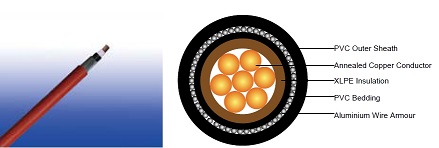

600/1000V XLPE Insulated, PVC Sheathed, Armoured Power Cables to BS 5467 (Single Core)

FGD300 1RVMAV-R (CU/XLPE/PVC/AWA/PVC 600/1000V Class 2)

BS Code: 6941X

Application

The cables are mainly used in power stations, mass transit underground passenger systems, airports, petrochemical plants, hotels, hospitals, and high-rise buildings. This product type is TUV approved.

Standards

Basic design to to BS 5467

Approvals

TUV Certification (Z1 17 01 98200 003)

Fire Performance

| Flame Retardance (Single Vertical Wire Test) |

BS EN 60332-1-2 |

Voltage Rating

600/1000V

Cable Construction

| Conductor |

Annealed copper wire, stranded according to BS EN 60228 class 2. |

| Insulation |

Extruded XLPE GP 8 according to BS 7655-1.3. |

| Bedding |

PVC or polymeric compound. |

| Armouring |

Aluminium wire |

| Outer Sheath |

PVC Type 9 according to BS 7655-4.2. |

| Outer Sheath Option |

UV resistance, hydrocarbon resistance, oil resistance, anti rodent and anti termite properties can be offered as option. Compliance to fire performance standard (IEC 60332-1, IEC 60332-3, UL 1581, UL 1666 etc) depends on the oxygen index of the PVC compound and the overall cable design. LSPVC can also be provided upon request. |

Colour Code

| Insulation Colour |

Brown or blue |

| Sheath Colour |

Black, other colours can be offered upon request. |

Mechanical and Electrical Properties

| Maximum temperature range during operation (XLPE) |

90°C |

| Maximum short circuit temperature (5 Seconds) |

250°C |

| Minimum bending radius |

| Circular copper conductors |

6 x Overall Diameter |

| Shaped copper conductors |

8 x Overall Diameter |

Construction Parameters

| Conductor |

FGD300 1RVMAV-R |

| No. of Cores xCross Section |

Class of Conductor |

Nominal Insulation Thickness |

Nominal Bedding Thickness |

Nominal Armour Wire Diameter |

Nominal Sheath Thickness |

Approx. Overall Diameter |

Approx. Weight |

| No.xmm² |

|

mm |

mm |

mm |

mm |

mm |

kg/km |

| 1x50 |

2 |

1.0 |

0.8 |

0.9 |

1.5 |

17.5 |

800 |

| 1x70 |

2 |

1.1 |

0.8 |

1.25 |

1.5 |

20.2 |

990 |

| 1x95 |

2 |

1.1 |

0.8 |

1.25 |

1.6 |

22.3 |

1280 |

| 1x120 |

2 |

1.2 |

0.8 |

1.25 |

1.6 |

24.2 |

1550 |

| 1x150 |

2 |

1.4 |

1.0 |

1.6 |

1.7 |

27.4 |

1900 |

| 1x185 |

2 |

1.6 |

1.0 |

1.6 |

1.8 |

30 |

2320 |

| 1x240 |

2 |

1.7 |

1.0 |

1.6 |

1.8 |

32.8 |

2930 |

| 1x300 |

2 |

1.8 |

1.0 |

1.6 |

1.9 |

35.6 |

3580 |

| 1x400 |

2 |

2.0 |

1.2 |

2.0 |

2.0 |

40.5 |

4600 |

| 1x500 |

2 |

2.2 |

1.2 |

2.0 |

2.1 |

44.2 |

5680 |

| 1x630 |

2 |

2.4 |

1.2 |

2.0 |

2.2 |

48.8 |

7160 |

| 1x800 |

2 |

2.6 |

1.4 |

2.5 |

2.4 |

55.4 |

9315 |

| 1x1000 |

2 |

2.8 |

1.4 |

2.5 |

2.5 |

60.6 |

11490 |

ELECTRICAL PROPERTIES

| Conductor Operating Temperature |

90°C |

| Ambient Temperature |

30°C |

Current-Carrying Capacities (Amp) according to BS 7671: 2008 table 4E3A

| Conductor cross-sectional area |

Reference Method C (clipped direct) |

Reference Method F (in free air or on a perforated cable tray, horizontal or vertical) |

| Touching |

Touching |

Spaced by on cable diameter |

| 2 cables, single-phase a.c. or d.c. flat |

3 or 4 cables, three-phase a.c. flat |

2 cables, single-hase a.c. or d.c. flat |

3 or 4 cables, three-phase a.c. flat |

3 cables three-phase a.c. trefoil |

2 cables, d.c. |

2 cables, single-phase a.c. |

3 or 4 cables, three-phase a.c. |

| Horizontal |

Vertical |

Horizontal |

Vertical |

Horizontal |

Vertical |

| 1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

| mm2 |

A |

A |

A |

A |

A |

A |

A |

A |

A |

A |

A |

| 50 |

237 |

220 |

253 |

232 |

222 |

284 |

270 |

282 |

266 |

288 |

266 |

| 70 |

303 |

277 |

322 |

293 |

285 |

356 |

349 |

357 |

337 |

358 |

331 |

| 95 |

367 |

333 |

389 |

352 |

346 |

446 |

426 |

436 |

412 |

425 |

393 |

| 120 |

425 |

383 |

449 |

405 |

402 |

519 |

497 |

504 |

477 |

485 |

449 |

| 150 |

488 |

437 |

516 |

462 |

463 |

600 |

575 |

566 |

539 |

549 |

510 |

| 185 |

557 |

496 |

587 |

524 |

529 |

688 |

660 |

643 |

614 |

618 |

574 |

| 240 |

656 |

579 |

689 |

612 |

625 |

815 |

782 |

749 |

714 |

715 |

666 |

| 300 |

755 |

662 |

792 |

700 |

720 |

943 |

906 |

842 |

805 |

810 |

755 |

| 400 |

853 |

717 |

899 |

767 |

815 |

1137 |

1094 |

929 |

889 |

848 |

797 |

| 500 |

962 |

791 |

1016 |

851 |

918 |

1314 |

1266 |

1032 |

989 |

923 |

871 |

| 630 |

1082 |

861 |

1146 |

935 |

1027 |

1528 |

1474 |

1139 |

1092 |

992 |

940 |

| 800 |

1170 |

904 |

1246 |

987 |

1119 |

1809 |

1744 |

1204 |

1155 |

1042 |

978 |

| 1000 |

1261 |

961 |

1345 |

1055 |

1214 |

2100 |

2026 |

1289 |

1238 |

1110 |

1041 |

Voltage Drop (Per Amp Per Meter) according to BS 7671: 2008 table 4E3B

| Nominal Cross Section Area |

2 cables d.c. |

Ref. Methods C&F(clipped direct, on trays or in free air) |

| 2 cables, single-phase a.c. |

3 or 4 cables, three-phase a.c. |

| Touching |

Spaced* |

Trefoil and touching |

Flat and touching |

Flat and spaced* |

| 1 |

2 |

3 |

4 |

5 |

6 |

7 |

| mm2 |

mV/A/m |

mV/A/m |

mV/A/m |

mV/A/m |

mV/A/m |

mV/A/m |

| |

|

r |

x |

z |

r |

x |

z |

r |

x |

z |

r |

x |

z |

r |

x |

z |

| 50 |

0.98 |

0.99 |

0.21 |

1.0 |

0.98 |

0.29 |

1.0 |

0.86 |

0.18 |

0.87 |

0.64 |

0.25 |

0.88 |

0.84 |

0.33 |

0.9 |

| 70 |

0.67 |

0.68 |

0.20 |

0.71 |

0.69 |

0.29 |

0.75 |

0.59 |

0.170 |

0.62 |

0.60 |

0.25 |

0.65 |

0.62 |

0.32 |

0.70 |

| 95 |

0.49 |

0.51 |

0.195 |

0.55 |

0.53 |

0.28 |

0.60 |

0.44 |

0.170 |

0.47 |

0.46 |

0.24 |

0.52 |

0.49 |

0.31 |

0.58 |

| 120 |

0.39 |

0.41 |

0.190 |

0.45 |

0.43 |

0.27 |

0.51 |

0.35 |

0.165 |

0.39 |

0.38 |

0.24 |

0.44 |

0.41 |

0.30 |

0.51 |

| 150 |

0.31 |

0.33 |

0.185 |

0.38 |

0.36 |

0.27 |

0.45 |

0.29 |

0.160 |

0.33 |

0.31 |

0.23 |

0.39 |

0.34 |

0.29 |

0.45 |

| 185 |

0.25 |

0.27 |

0.185 |

0.33 |

0.30 |

0.26 |

0.40 |

0.23 |

0.160 |

0.28 |

0.26 |

0.23 |

0.34 |

0.29 |

0.29 |

0.41 |

| 240 |

0.195 |

0.21 |

0.180 |

0.28 |

0.24 |

0.26 |

0.35 |

0.180 |

0.155 |

0.24 |

0.21 |

0.22 |

0.30 |

0.24 |

0.28 |

0.37 |

| 300 |

0.155 |

0.17 |

0.175 |

0.25 |

0.195 |

0.25 |

0.32 |

0.145 |

0.150 |

0.21 |

0.170 |

0.22 |

0.28 |

0.20 |

0.27 |

0.34 |

| 400 |

0.115 |

0.145 |

0.170 |

0.22 |

0.180 |

0.24 |

0.30 |

0.125 |

0.150 |

0.195 |

0.160 |

0.21 |

0.27 |

0.20 |

0.27 |

0.33 |

| 500 |

0.093 |

0.125 |

0.170 |

0.21 |

0.165 |

0.24 |

0.29 |

0.105 |

0.145 |

0.180 |

0.145 |

0.20 |

0.25 |

0.190 |

0.24 |

0.31 |

| 630 |

0.073 |

0.105 |

0.165 |

0.195 |

0.150 |

0.23 |

0.27 |

0.092 |

0.145 |

0.170 |

0.135 |

0.195 |

0.24 |

0.175 |

0.23 |

0.29 |

| 800 |

0.056 |

0.090 |

0.160 |

0.190 |

0.145 |

0.23 |

0.27 |

0.086 |

0.140 |

0.165 |

0.130 |

0.180 |

0.23 |

0.175 |

0.195 |

0.26 |

| 1000 |

0.045 |

0.092 |

0.155 |

0.180 |

0.140 |

0.21 |

0.25 |

0.080 |

0.135 |

0.155 |

0.125 |

0.170 |

0.21 |

0.165 |

0.180 |

0.24 |

Note: *Spacings larger than one cable diameter will result in a large voltage drop.

r = conductor resistance at operating temperature

x = reactance

z = impedance