300/500V LSZH Insulated, Non-sheathed Power Cables to BS EN 50525-3-31 (Single Core)

FTX100 05Z1-U/R/K (CU/LSZH 300/500V Class 1/2/5)

HAR Code: H05Z1-U/R/K

Application

The cables are mainly used in power stations, mass transit underground passenger systems, airports, petrochemical plants, hotels, hospitals, and high-rise buildings.

Standards

Basic design to BS EN 50525-3-31

Fire Performance

Flame Retardance |

EN 60332-1-2; IEC 60332-1-2 |

Reduced Fire Propagation |

EN 60332-3-24; IEC 60332-3-24 |

Halogen Free |

IEC 60754-1; EN 50267-2-1 |

No Corrosive Gas Emission |

IEC 60754-2; EN 50267-2-2 |

Minimum Smoke Emission |

IEC 61034-2; EN 61034 -2 |

Voltage Rating

300/500V

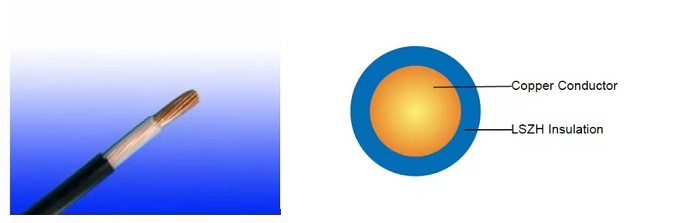

Cable Construction

Conductor: Copper conductor according to BS EN 60228 class 1/2/5.

Insulation: Thermoplastic compound of type TI 7 to EN 50363-7.

Insulation Option: UV resistance, hydrocarbon resistance, oil resistance, anti-rodent and anti-termite properties can be offered as option.

Colour Code

Black, Blue, Brown, Grey, Orange, Pink, Red, Turquoise, Violet, White, Green and Yellow. Bi-colours of any combination of the above mono-colours are permitted.

Physical And Thermal Properties

Maximum temperature range during operation: 70°C

Maximum short circuit temperature (5 Seconds): 160°C

Minimum bending radius: 4 x Overall Diameter

Construction Parameters

| Conductor | FTX100 05Z1-U/R/K | ||||

|---|---|---|---|---|---|

| No. of Cores × Cross-sectional Area | Conductor Class | Nominal Insulation Thickness | Min. Overall Diameter | Max. Overall Diameter | Approx. Weight |

| No.×mm² | mm | mm | mm | kg/km | |

| 1×0.50 | 1 | 0.6 | 1.9 | 2.3 | 9.4 |

| 1×0.75 | 1 | 0.6 | 2.1 | 2.5 | 12.2 |

| 1×1.0 | 1 | 0.6 | 2.2 | 2.7 | 15.4 |

| 1×0.50 | 2 | 0.6 | 2.0 | 2.4 | 10.1 |

| 1×0.75 | 2 | 0.6 | 2.2 | 2.6 | 13.0 |

| 1×1.0 | 2 | 0.6 | 2.3 | 2.8 | 16.8 |

| 1×0.50 | 5 | 0.6 | 2.1 | 2.5 | 9.9 |

| 1×0.75 | 5 | 0.6 | 2.2 | 2.7 | 13.3 |

| 1×1.0 | 5 | 0.6 | 2.4 | 2.8 | 16.2 |

Electrical Properties

Conductor Operating Temperature : 70°C

Ambient Temperature : 30°C

Current-Carrying Capacities (Amp)

| Conductor Cross-Sectional Area | Single-phase a.c. | Three-phase a.c. |

|---|---|---|

| mm² | A | A |

| 0.5 | 3 | 3 |

| 0.75 | 6 | 6 |

| 1.0 | 10 | 10 |

|

Note: These values apply to the majority of cases. Further information should be sought in unusual cases eg.: (i) When high ambient temperatures are involved, ie. above 30°C (ii) Where long lengths are used (iii) Where ventilation is restricted (iv) Where the cords are used for other purposes, ego internal wiring of apparatus. |

||

Voltage Drop (Per Amp Per Meter)

| Conductor cross-sectional area | 2 cables d.c. | 2 cables, single-phase a.c. | 3 or 4 cables, three-phase a.c. | |||||

|---|---|---|---|---|---|---|---|---|

| Ref. Methods A&B (enclosed in conduit or trunking) | Ref. Methods C, F&G (clipped direct, on trays or in free air) | Ref. Methods A&B (enclosed in conduit or trunking) | Ref. Methods C, F&G (clipped direct, on trays or in free air) | |||||

| Cables touching | Cables spaced* | Cables touching, Trefoil | Cables touching, flat | Cables spaced*, flat | ||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| mm² | mV/A/m | mV/A/m | mV/A/m | mV/A/m | mV/A/m | mV/A/m | mV/A/m | mV/A/m |

| 0.5 | 93 | 93 | 93 | 93 | 80 | 80 | 80 | 80 |

| 0.75 | 62 | 62 | 62 | 62 | 54 | 54 | 54 | 54 |

| 1.0 | 46 | 46 | 46 | 46 | 40 | 40 | 40 | 40 |

Note: *Spacings larger than one cable diameter will result in a large voltage drop.