TPEE Insulated PUR Sheathed Cables with Screen, Paired

Application

These cables are used as connecting cables for power supply and, at the same time, as motor control cable. They are used for permanent flexible applications in machineries, machine tools, robot technics, for movable automated machinery parts and multi-shift operation. The adhesion-free PUR outer sheath is characterized by its high impact strength, excellent oil and UV resistance and superior chemical resistance and thus ensures a long cable service life.

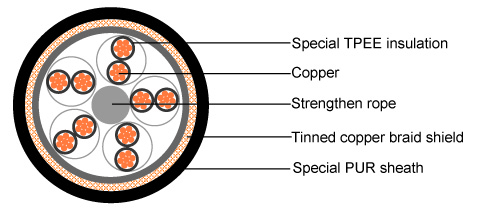

Cable Construction

| Conductor | VDE0295 Class 6 |

| Insulation | Special TPEE mixture |

| Reinforce | Special tensile strengthen rope/core |

| Screen | Tinned copper braid shield |

| Sheath | Special low viscosity wear resistant PUR mixture |

Dimensions and Weight

No.of Pairs |

Conductor Cross-Sectional Area | Strands Number and Dia. of Wires | Nominal Dia. of Cable | Max. Dia. of Cable | Approx. Weight |

| mm² | No./mm | mm | mm | kg/km | |

| 1 | 0.14 | 19/0.10 | 4.2 | 5.0 | 28 |

| 2 | 0.14 | 19/0.10 | 5.4 | 6.2 | 42 |

| 3 | 0.14 | 19/0.10 | 5.8 | 6.6 | 51 |

| 4 | 0.14 | 19/0.10 | 6.2 | 7.0 | 60 |

| 5 | 0.14 | 19/0.10 | 6.6 | 7.4 | 66 |

| 6 | 0.14 | 19/0.10 | 7.1 | 7.9 | 75 |

| 8 | 0.14 | 19/0.10 | 7.5 | 8.3 | 86 |

| 10 | 0.14 | 19/0.10 | 8.7 | 9.6 | 109 |

| 1 | 0.25 | 19/0.13 |

4.5 | 5.0 | 32 |

| 2 | 0.25 | 19/0.13 |

6.1 | 6.7 | 53 |

| 3 | 0.25 | 19/0.13 |

6.3 | 7.0 | 63 |

| 4 | 0.25 | 19/0.13 |

6.8 | 7.5 | 74 |

| 5 | 0.25 | 19/0.13 |

7.3 | 8.0 | 83 |

| 6 | 0.25 | 19/0.13 |

7.8 | 8.6 | 95 |

| 8 | 0.25 | 19/0.13 |

8.5 | 9.4 | 115 |

| 10 | 0.25 | 19/0.13 |

9.7 | 10.7 | 141 |

| 1 | 0.34 | 19/0.15 | 5.8 | 6.6 | 52 |

| 2 | 0.34 | 19/0.15 | 7.6 | 8.6 | 83 |

| 3 | 0.34 | 19/0.15 | 8.0 | 9.0 | 96 |

| 4 | 0.34 | 19/0.15 | 8.9 | 9.9 | 121 |

| 5 | 0.34 | 19/0.15 | 9.5 | 10.5 | 139 |

| 6 | 0.34 | 19/0.15 | 10.1 | 11.2 | 158 |

| 8 | 0.34 | 19/0.15 | 11.8 | 13.0 | 203 |

| 10 | 0.34 | 19/0.15 | 12.5 | 13.7 | 228 |

| 1 | 0.5 | 16/0.20 | 6.4 | 7.3 | 64 |

| 2 | 0.5 | 16/0.20 | 8.6 | 9.5 | 103 |

| 3 | 0.5 | 16/0.20 | 9.2 | 10.1 | 126 |

| 4 | 0.5 | 16/0.20 | 9.8 | 10.8 | 147 |

| 5 | 0.5 | 16/0.20 | 10.5 | 11.6 | 171 |

| 6 | 0.5 | 16/0.20 | 11.5 | 12.6 | 201 |

| 8 | 0.5 | 16/0.20 | 13.2 | 14.5 | 254 |

| 10 | 0.5 | 16/0.20 | 14.2 | 15.6 | 293 |

| 1 | 0.75 | 24/0.20 | 6.9 | 7.8 | 74 |

| 2 | 0.75 | 24/0.20 | 9.5 | 10.4 | 126 |

| 3 | 0.75 | 24/0.20 | 9.9 | 10.9 | 151 |

| 4 | 0.75 | 24/0.20 | 10.6 | 11.7 | 181 |

| 5 | 0.75 | 24/0.20 | 11.7 | 12.8 | 217 |

| 6 | 0.75 | 24/0.20 | 12.5 | 13.8 | 247 |

| 8 | 0.75 | 24/0.20 | 14.9 | 16.4 | 334 |

| 10 | 0.75 | 24/0.20 | 15.7 | 17.3 | 374 |

| 1 | 1 | 32/0.20 | 7.4 | 8.3 | 87 |

| 2 | 1 | 32/0.20 | 10.4 | 11.4 | 150 |

| 3 | 1 | 32/0.20 | 10.9 | 12.0 | 181 |

| 4 | 1 | 32/0.20 | 11.9 | 13.1 | 224 |

| 5 | 1 | 32/0.20 | 12.9 | 14.1 | 263 |

| 6 | 1 | 32/0.20 | 14.0 | 15.4 | 309 |

| 8 | 1 | 32/0.20 | 16.7 | 18.4 | 411 |

| 10 | 1 | 32/0.20 | 17.7 | 19.5 | 471 |

| 1 | 1.5 | 48/0.20 | 8.2 | 9.1 | 107 |

| 2 | 1.5 | 48/0.20 | 11.9 | 13.1 | 194 |

| 3 | 1.5 | 48/0.20 | 12.5 | 13.7 | 239 |

| 4 | 1.5 | 48/0.20 | 13.5 | 14.9 | 292 |

| 5 | 1.5 | 48/0.20 | 15.0 | 16.5 | 359 |

| 6 | 1.5 | 48/0.20 | 16.2 | 17.8 | 415 |

| 8 | 1.5 | 48/0.20 | 19.6 | 21.5 | 574 |

| 10 | 1.5 | 48/0.20 | 20.9 | 23.0 | 670 |