TPEE Insulated PUR Sheathed Cables with Screen, Paired

Application

These cables are used as power and control cables or connecting cables. They are suitable for automatic production line, control unit, factory cabling, office equipment, etc.

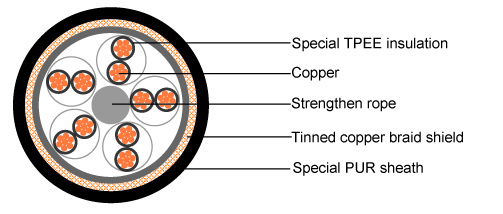

Cable Construction

| Conductor | Annealed flexible copper |

| Insulation | Special TPEE mixture |

| Reinforce | Special tensile strengthen rope/core |

| Screen | Tinned copper braid shield |

| Sheath | Special low viscosity wear resistant PUR mixture |

Technical Properties

- Voltage: 300V

- Test voltage: 1500V/5min(AC)

- Minimum bend radius: Fixed installation: 5xOD

- Temperature range: Fixed installation: -50~90℃

- Retardant properties: Complied with IEC60332-1

Dimensions and Weight

No.of Pairs |

Conductor Cross-Sectional Area | Strands Number and Dia. of Wires | Nominal Dia. of Cable | Max. Dia. of Cable | Approx. Weight |

| mm² | No./mm | mm | mm | kg/km | |

| 1 | 0.14 | 19/0.10 | 4.2 | 5.0 | 28 |

| 2 | 0.14 | 19/0.10 | 5.4 | 6.2 | 42 |

| 3 | 0.14 | 19/0.10 | 5.8 | 6.6 | 51 |

| 4 | 0.14 | 19/0.10 | 6.2 | 7.0 | 60 |

| 5 | 0.14 | 19/0.10 | 6.6 | 7.4 | 66 |

| 6 | 0.14 | 19/0.10 | 7.1 | 8.0 | 75 |

| 8 | 0.14 | 19/0.10 | 7.5 | 8.3 | 86 |

| 10 | 0.14 | 19/0.10 | 8.7 | 9.6 | 109 |

| 1 | 0.25 | 19/0.13 |

4.5 | 5.3 | 32 |

| 2 | 0.25 | 19/0.13 |

6.1 | 6.9 | 53 |

| 3 | 0.25 | 19/0.13 |

6.3 | 7.1 | 63 |

| 4 | 0.25 | 19/0.13 |

6.8 | 7.6 | 74 |

| 5 | 0.25 | 19/0.13 |

7.3 | 8.1 | 83 |

| 6 | 0.25 | 19/0.13 |

7.8 | 8.6 | 95 |

| 8 | 0.25 | 19/0.13 |

8.5 | 9.4 | 115 |

| 10 | 0.25 | 19/0.13 |

9.7 | 10.7 | 141 |

| 1 | 0.34 | 19/0.15 | 5.1 | 5.9 | 41 |

| 2 | 0.34 | 19/0.15 | 7.0 | 7.8 | 68 |

| 3 | 0.34 | 19/0.15 | 7.3 | 8.1 | 81 |

| 4 | 0.34 | 19/0.15 | 7.9 | 8.8 | 96 |

| 5 | 0.34 | 19/0.15 | 8.7 | 9.6 | 116 |

| 6 | 0.34 | 19/0.15 | 9.3 | 10.2 | 134 |

| 8 | 0.34 | 19/0.15 | 9.9 | 10.9 | 156 |

| 10 | 0.34 | 19/0.15 | 11.6 | 12.8 | 198 |

| 1 | 0.5 | 16/0.20 | 5.8 | 6.6 | 52 |

| 2 | 0.5 | 16/0.20 | 7.7 | 8.5 | 83 |

| 3 | 0.5 | 16/0.20 | 8.1 | 9.0 | 100 |

| 4 | 0.5 | 16/0.20 | 9.0 | 9.9 | 124 |

| 5 | 0.5 | 16/0.20 | 9.7 | 10.6 | 146 |

| 6 | 0.5 | 16/0.20 | 10.4 | 11.5 | 169 |

| 8 | 0.5 | 16/0.20 | 11.4 | 12.5 | 204 |

| 10 | 0.5 | 16/0.20 | 13.1 | 14.4 | 253 |

| 1 | 0.75 | 24/0.20 | 6.2 | 7.0 | 61 |

| 2 | 0.75 | 24/0.20 | 8.6 | 9.5 | 103 |

| 3 | 0.75 | 24/0.20 | 9.1 | 10.0 | 127 |

| 4 | 0.75 | 24/0.20 | 9.8 | 10.8 | 155 |

| 5 | 0.75 | 24/0.20 | 10.6 | 11.7 | 184 |

| 6 | 0.75 | 24/0.20 | 11.7 | 12.8 | 217 |

| 8 | 0.75 | 24/0.20 | 12.5 | 13.8 | 260 |

| 10 | 0.75 | 24/0.20 | 14.7 | 16.2 | 329 |

| 1 | 1 | 32/0.20 | 6.8 | 7.6 | 72 |

| 2 | 1 | 32/0.20 | 9.5 | 10.5 | 124 |

| 3 | 1 | 32/0.20 | 10.0 | 11.0 | 155 |

| 4 | 1 | 32/0.20 | 10.9 | 12.0 | 190 |

| 5 | 1 | 32/0.20 | 12.0 | 13.2 | 232 |

| 6 | 1 | 32/0.20 | 13.0 | 14.3 | 270 |

| 8 | 1 | 32/0.20 | 14.2 | 15.6 | 332 |

| 10 | 1 | 32/0.20 | 16.7 | 18.3 | 421 |

| 1 | 1.5 | 48/0.20 | 7.6 | 8.4 | 91 |

| 2 | 1.5 | 48/0.20 | 10.8 | 11.9 | 161 |

| 3 | 1.5 | 48/0.20 | 11.6 | 12.8 | 209 |

| 4 | 1.5 | 48/0.20 | 12.7 | 13.9 | 259 |

| 5 | 1.5 | 48/0.20 | 14.0 | 15.4 | 316 |

| 6 | 1.5 | 48/0.20 | 15.2 | 16.7 | 368 |

| 8 | 1.5 | 48/0.20 | 16.3 | 18.0 | 451 |

| 10 | 1.5 | 48/0.20 | 19.7 | 21.7 | 600 |