| Industrial Cables | |||

| American | British | German | Harmonized | Italian | JIS | French |

Spanish Standard Industrial Cables

DN-F

Application and Description

Flexible cable for mobile heavy duty. Suitable for installations in dry, damp or wet locations, outdoors, for hazardous areas with explosive gas atmospheres, machines in industrial workshops, motors and transportable machines; on construction sites and for agricultural exploitations. Suitable for submerged installations (AD8).

Standard and Approval

UNE 21150, UNE 21166, EN 60332-1, IEC 60332-1

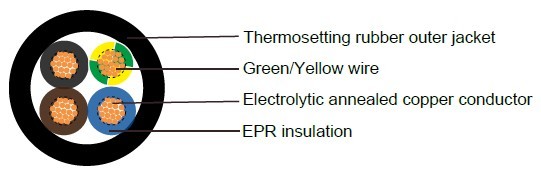

Cable Construction

- Flexible electrolytic annealed copper conductor

- Class 5 or class 6 in accordance with IEC 60228.

- Thermosetting rubber type EPR insulation

- Color coded to HD308 and HD186, 6 or more conductors: black numbered + green/yellow

- Green-yellow grounding, 3 conductors and above

- Thermosetting rubber type SE1 outer sheath

Technical Characteristics

- Working voltage: 600/1000 volts

- Test voltage: 2000 volts

- Minimum bending radius: 3 x Ø

- Working temperature: -25º C to +90º C

- Short circuit temperature: +250º C

- Flame retardant: IEC 60332.1

- Insulation resistance: 20 MΩ x km

Cable Parameter

| AWG | NO. OF CORES X NOMINAL CROSS SECTIONAL AREA # X MM² |

NOMINAL OVERALL DIAMETER MM |

NOMINAL WEIGHTKG/KM | AWG | NO. OF CORES X NOMINAL CROSS SECTIONAL AREA # X MM² |

NOMINAL OVERALL DIAMETER MM |

NOMINAL WEIGHT KG/KM |

| 10(84/28) | 1×6 | 8.3 | 113 | 16(30/30) | 3×1.5 | 10.9 | 163 |

| 8(80/26) | 1×10 | 10.0 | 176 | 14(50/30) | 3×2.5 | 12.2 | 216 |

| 6(128/26) | 1×16 | 11.1 | 242 | 12(56/28) | 3×4 | 13.9 | 296 |

| 4(200/26) | 1×25 | 13.2 | 353 | 10(84/28) | 3×6 | 15.4 | 385 |

| 2 (280/26) | 1×35 | 14.7 | 470 | 8(80/26) | 3×10 | 20.0 | 646 |

| 1(400/26) | 1×50 | 17.1 | 645 | 6(128/26) | 3×16 | 22.3 | 876 |

| 2/0 (356/24) |

1×70 | 19.2 | 865 | 4(200/26) | 3×25 | 26.8 | 1292 |

| 3/0 (485/24) |

1×95 | 21.7 | 1121 | 2(280/26) | 3×35 | 29.7 | 1691 |

| 4/0 (614/24) |

1×120 | 23.4 | 1393 | 1(400/26) | 3×50 | 35.4 | 2357 |

| 300 MCM (765/24) |

1×150 | 25.9 | 1717 | 2/0 (356/24) |

3×70 | 39.6 | 3118 |

| 350 MCM (944/24) |

1×185 | 28.8 | 2079 | 3/0 (485/24) |

3×95 | 45.1 | 4068 |

| 500MCM (1225/24) |

1×240 | 31.9 | 2668 | 16(30/30) | 4×1.5 | 11.9 | 199 |

| - | 1×300 | 34.9 | 3272 | 14(50/30) | 4×2.5 | 13.5 | 269 |

| 16(30/30) | 2×1.5 | 9.3 | 115 | 12(56/28) | 4×4 | 15.9 | 387 |

| 14(50/30) | 2×2.5 | 10.7 | 166 | 10(84/28) | 4×6 | 18.1 | 516 |

| 12(56/28) | 2×4 | 12.3 | 226 | 8(80/26) | 4×10 | 21.5 | 790 |

| 10(84/28) | 2×6 | 13.6 | 286 | 6(128/26) | 4×16 | 24.2 | 1081 |

| 8(80/26) | 2×10 | 18.0 | 505 | ||||

| 6(128/26) | 2×16 | 21.3 | 713 | ||||

| 4(200/26) | 2×25 | 25.7 | 1050 |