CVVAMS

Application and Description:

Used for electric signal transmission of control or monitoring circuits for 0.6/1kV

Reference Standard:

IEC 60502-1

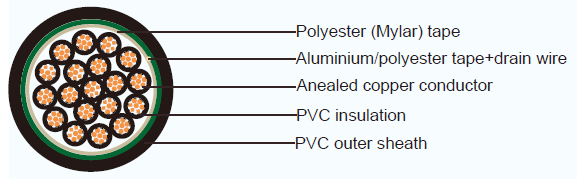

Cable Construction:

Conductor: Stranded annealed copper wires, Sizes: 1.5 mm2 up to 10 mm2 Insulation: Polyvinyl chloride (PVC)

Color : Black with marking numbers Filler: Non-hygroscopic material(optional)

Binding tape: Polyester (Mylar) tape (optional)

Overall Screen 1: Aluminium/polyester tape is applied over each pair metallic side down in contact with tinned copper drain wire.

Sheath: Polyvinyl chloride (PVC), Black color (other colors can be provided upn request)

Technical Characteristics:

Maximum conductor temperature 70oC

Circuit voltage not exceeding 600 volts

Test voltage: 3500 volts

Cable Parameter:

| NO. OF CORES | CONDUCTOR | THICKNESS OF INSULATION | THICKNESS OF OUTER SHEATH |

OVERALL DIAMETER | MAXIMUM CONDUCTOR RESISTANCE (AT 20°C) | CABLE WEIGHT | ||

| NOMINAL CROSS- SECTIONAL AREA |

NO.& DIA. OF WIRES |

DIAMETER | ||||||

| MM2 | MM | MM | MM | MM | MM | OHM/KM | KG/KM | |

| 2 | 1.5 | 7/0.53 | 1.59 | 0.8 | 1.8 | 12 | 12.1 | 160 |

| 2.5 | 7/0.67 | 2.01 | 0.8 | 1.8 | 13 | 7.41 | 190 | |

| 4 | 7/0.85 | 2.55 | 1 | 1.8 | 14.5 | 4.61 | 260 | |

| 6 | 7/1.04 | 3.12 | 1 | 1.8 | 16 | 3.08 | 320 | |

| 10 | 7/1.35 | 4.05 | 1 | 1.8 | 17.5 | 1.83 | 430 | |

| 3 | 1.5 | 7/0.53 | 1.59 | 0.8 | 1.8 | 12.5 | 12.1 | 190 |

| 2.5 | 7/0.67 | 2.01 | 0.8 | 1.8 | 13.5 | 7.41 | 240 | |

| 4 | 7/0.85 | 2.55 | 1 | 1.8 | 15.5 | 4.61 | 330 | |

| 6 | 7/1.04 | 3.12 | 1 | 1.8 | 17 | 3.08 | 410 | |

| 10 | 7/1.35 | 4.05 | 1 | 1.8 | 18.5 | 1.83 | 570 | |

| 4 | 1.5 | 7/0.53 | 1.59 | 0.8 | 1.8 | 13.5 | 12.1 | 230 |

| 2.5 | 7/0.67 | 2.01 | 0.8 | 1.8 | 14.5 | 7.41 | 290 | |

| 4 | 7/0.85 | 2.55 | 1 | 1.8 | 16.5 | 4.61 | 410 | |

| 6 | 7/1.04 | 3.12 | 1 | 1.8 | 18 | 3.08 | 520 | |

| 10 | 7/1.35 | 4.05 | 1 | 1.8 | 20.5 | 1.83 | 720 | |

| 5 | 1.5 | 7/0.53 | 1.59 | 0.8 | 1.8 | 14.5 | 12.1 | 270 |

| 2.5 | 7/0.67 | 2.01 | 0.8 | 1.8 | 15.5 | 7.41 | 340 | |

| 4 | 7/0.85 | 2.55 | 1 | 1.8 | 18 | 4.61 | 490 | |

| 6 | 7/1.04 | 3.12 | 1 | 1.8 | 19.5 | 3.08 | 630 | |

| 10 | 7/1.35 | 4.05 | 1 | 1.8 | 22.5 | 1.83 | 870 | |

| 6 | 1.5 | 7/0.53 | 1.59 | 0.8 | 1.8 | 15.5 | 12.1 | 310 |

| 2.5 | 7/0.67 | 2.01 | 0.8 | 1.8 | 16.5 | 7.41 | 400 | |

| 4 | 7/0.85 | 2.55 | 1 | 1.8 | 19.5 | 4.61 | 580 | |

| 6 | 7/1.04 | 3.12 | 1 | 1.8 | 21.5 | 3.08 | 740 | |

| 10 | 7/1.35 | 4.05 | 1 | 1.8 | 24.5 | 1.83 | 1040 | |

| 7 | 1.5 | 7/0.53 | 1.59 | 0.8 | 1.8 | 15.5 | 12.1 | 340 |

| 2.5 | 7/0.67 | 2.01 | 0.8 | 1.8 | 16.5 | 7.41 | 430 | |

| 4 | 7/0.85 | 2.55 | 1 | 1.8 | 19.5 | 4.61 | 630 | |

| 6 | 7/1.04 | 3.12 | 1 | 1.8 | 21.5 | 3.08 | 810 | |

| 10 | 7/1.35 | 4.05 | 1 | 1.8 | 24.5 | 1.83 | 1150 | |

| 8 | 1.5 | 7/0.53 | 1.59 | 0.8 | 1.8 | 16.5 | 12.1 | 390 |

| 2.5 | 7/0.67 | 2.01 | 0.8 | 1.8 | 17.5 | 7.41 | 490 | |

| 4 | 7/0.85 | 2.55 | 1 | 1.8 | 21.5 | 4.61 | 730 | |

| 6 | 7/1.04 | 3.12 | 1 | 1.8 | 23.5 | 3.08 | 940 | |

| 10 | 7/1.35 | 4.05 | 1 | 1.8 | 26.5 | 1.83 | 1330 | |

| 10 | 1.5 | 7/0.53 | 1.59 | 0.8 | 1.8 | 18.5 | 12.1 | 470 |

| 2.5 | 7/0.67 | 2.01 | 0.8 | 1.8 | 20.5 | 7.41 | 600 | |

| 4 | 7/0.85 | 2.55 | 1 | 1.8 | 24.5 | 4.61 | 890 | |

| 6 | 7/1.04 | 3.12 | 1 | 1.8 | 26.5 | 3.08 | 1150 | |

| 10 | 7/1.35 | 4.05 | 1 | 1.8 | 30.5 | 1.83 | 1640 | |

| 12 | 1.5 | 7/0.53 | 1.59 | 0.8 | 1.8 | 18.5 | 12.1 | 530 |

| 2.5 | 7/0.67 | 2.01 | 0.8 | 1.8 | 20.5 | 7.41 | 690 | |

| 4 | 7/0.85 | 2.55 | 1 | 1.8 | 25.5 | 4.61 | 1030 | |

| 6 | 7/1.04 | 3.12 | 1 | 1.8 | 27.5 | 3.08 | 1330 | |

| 10 | 7/1.35 | 4.05 | 1 | 1.8 | 31.5 | 1.83 | 1910 | |

| 15 | 1.5 | 7/0.53 | 1.59 | 0.8 | 1.8 | 20.5 | 12.1 | 640 |

| 2.5 | 7/0.67 | 2.01 | 0.8 | 1.8 | 22.5 | 7.41 | 830 | |

| 4 | 7/0.85 | 2.55 | 1 | 1.8 | 27.5 | 4.61 | 1250 | |

| 6 | 7/1.04 | 3.12 | 1 | 1.8 | 29.5 | 3.08 | 1630 | |

| 20 | 1.5 | 7/0.53 | 1.59 | 0.8 | 1.8 | 22 | 12.1 | 820 |

| 2.5 | 7/0.67 | 2.01 | 0.8 | 1.8 | 25.0 | 7.41 | 1070 | |

| 4 | 7/0.85 | 2.55 | 1 | 1.8 | 30.0 | 4.61 | 1630 | |

| 6 | 7/1.04 | 3.12 | 1 | 1.8 | 33 | 3.08 | 2130 | |

|

30 |

1.5 | 7/0.53 | 1.59 | 0.8 | 1.8 | 26 | 12.1 | 1160 |

| 2.5 | 7/0.67 | 2.01 | 0.8 | 1.8 | 29 | 7.41 | 1540 | |

| 4 | 7/0.85 | 2.55 | 1 | 1.9 | 36 | 4.61 | 2370 | |