|

| |

|

Industrial Cables |

Industrial Cables

N07G9-K

Application and Description

These cables are particularly suitable for installations in places at risk of fire and with a lot of people about. They are insulated with a special elastomer which ensures both their flame-retarding feature in the case of fire, in compliance with the IEC 332.3 standards, and their release of no halogens, toxic gases or smoke, in compliance with the IEC 754.1 standards. Suitable for fixed lay, in pipe, cable-carrier, channels, inner wiring of electric switchboards, inside interruption and control equipments for voltage until 1000V in c.a. and 750V d.c. to the ground.

Standard and Approval

- CEI 20-22 II, CEI 20-38, IEC 60332.3, IEC 60754.1, UNEL 35368, RoHS 2002/95/CE.

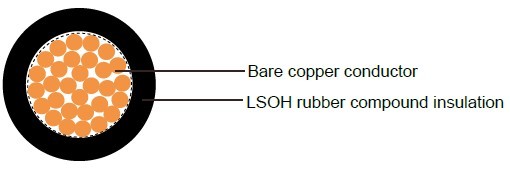

Cable Construction

| Fine bare copper or annealed copper strands |

| Strands to VDE-0295 Class-5, IEC 60228 Class-5 |

| Rubber type G9 LSOH insulation |

| Cores to VDE-0293 colors |

Technical Characteristics

| WORKING VOLTAGE |

450/750 v |

| TEST VOLTAGE |

2500 volts |

| MINIMUM BENDING RADIUS |

4.0 x Ø |

| FLEXING TEMPERATURE |

0º C to 90º C |

| STATIC TEMPERATURE |

-15º C to +90º C |

| FLAME RETARDANT |

IEC 60332.1 |

| INSULATION RESISTANCE |

10 MΩ x km |

Cable Parameter

| AWG |

NO. OF CORES X NOMINAL CROSS SECTIONAL AREA |

NOMINAL THICKNESS OF INSULATION |

NOMINAL OVERALL DIAMETER |

NOMINAL WEIGHT |

| |

# X MM² |

MM |

MM |

KG/KM |

| 17 (32/32) |

1 x 1 |

0.7 |

2.7 |

16 |

| 16 (30/30) |

1 x 1.5 |

0.7 |

3.1 |

20 |

| 14 (50/30) |

1 x 2.5 |

0.8 |

3.8 |

31 |

| 12 (56/28) |

1 x 4 |

0.8 |

4.2 |

45 |

| 10 (84/28) |

1 x 6 |

0.8 |

4.7 |

63 |

| 8 (80/26) |

1 x 10 |

1.0 |

6.0 |

112 |

| 6 (128/26) |

1 x 16 |

1.0 |

7.2 |

166 |

| 4 (200/26) |

1 x 25 |

1.2 |

9.4 |

254 |

| 2 (280/26) |

1 x 35 |

1.2 |

10.2 |

343 |

| 1 (400/26) |

1 x 50 |

1.4 |

11.5 |

485 |

| 2/0 (356/24) |

1 x 70 |

1.4 |

13.9 |

703 |

| 3/0 (485/24) |

1 x 95 |

1.6 |

15.7 |

928 |

| 4/0 (614/24) |

1 x 120 |

1,6 |

17.4 |

1200 |

| 300 MCM (765/24) |

1 x 150 |

1.8 |

19.6 |

1508 |

| 350 MCM (944/24) |

1 x 185 |

2.0 |

21.2 |

1817 |

| 500 MCM (1225/24) |

1 x 240 |

2.2 |

25.1 |

2336 |