| Industrial Cables | |||

| American | British | German | Harmonized | Italian | JIS | French |

Spanish Standard Industrial Cables

RC4Z1-K (AS) 0.6/1kV

Application and Description

The screened and halogen free cable is a high security cable. In case of fire, it does not emit toxic or corrosive gases, thereby protecting public health and avoiding any possible damage to electronic equipment. For this reason, its use is recommended for public places and for all installations where it is necessary avoid electric interference of nearby circuits.

Standard and Approval

UNE 21123-4, IEC 60502, EN 60332-1, EN 50266, EN 50267-1, EN 50267-2, EN 61034, IEC 60332-1, IEC 60332-3, IEC 60754-1, IEC 60754-2, IEC 61034

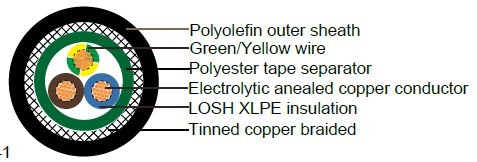

Cable Construction

- Rigid electrolytic annealed copper conductor

- Class 5 in accordance with IEC 60228.

- XLPE insulation, low smoke and halogen free, type DIX 3 according to HD 603

- Color coded to HD 308

- Polyester tape separator

- High coverage tinned copper braided screen

- Polyolefin outer sheath according to UNE 21123

Technical Characteristics

- Working voltage: 600/1000 volts

- Test voltage: 2000 volts

- Minimum bending radius: 10 x Ø

- Working temperature: -15º C to +90º C

- Short circuit temperature: +250º C

- Insulation resistance: 20 MΩ x km

- Halogen free: IEC 60754-1, EN 50267-2-1

- No corrosive gases: IEC 60754-2, EN 50267-2-2

- No toxic gases: NES 02-713, NF X 70-100

- Low smoke density: IEC 61034, EN 50268-2

- Flame retardant: IEC 60332-1, EN 50265-2-1

- Non-flame propagating: IEC 60332-3, EN 50266-2

Cable Parameter

| AWG | NO. OF CORES X NOMINAL CROSS SECTIONAL AREA # X MM² |

NOMINAL OVERALL DIAMETER MM |

NOMINAL WEIGHT KG/KM |

AWG | NO. OF CORES X NOMINAL CROSS SECTIONAL AREA # X MM² |

NOMINAL OVERALL DIAMETER MM |

NOMINAL WEIGHT KG/KM |

| 8(80/26) | 1×10 | 11.9 | 231 | 6(128/26) | 3×16 | 17.6 | 594 |

| 6(128/26) | 1×16 | 13.1 | 300 | 4(200/26) | 3×25 | 21.2 | 872 |

| 4(200/26) | 1×25 | 14.2 | 389 | 2(280/26) | 3×35 | 24.4 | 1195 |

| 2(280/26) | 1×35 | 15.3 | 489 | 1(400/26) | 3×50 | 28.6 | 1669 |

| 1(400/26) | 1×50 | 16.8 | 637 | 2/0(356/24) | 3×70 | 33.3 | 2301 |

| 2/0(356/24) | 1×70 | 18.7 | 835 | 16(30/30) | 4G1.5 | 10.3 | 141 |

| 3/0(485/24) | 1×95 | 21.1 | 1098 | 14(50/30) | 4G2.5 | 11.2 | 183 |

| 4/0(614/24) | 1×120 | 22.6 | 1331 | 12(56/28) | 4G4 | 13.1 | 275 |

| 300 MCM (765/24) |

1×150 | 24.7 | 1628 | 10(84/28) | 4G6 | 14.8 | 355 |

| 350 MCM (944/24) |

1×185 | 26.9 | 1975 | 8(80/26) | 4G10 | 17.1 | 529 |

| 500MCM (1225/24) |

1×240 | 30.0 | 2514 | 6(128/26) | 4×16 | 19.5 | 755 |

| - | 1×300 | 33.2 | 3114 | 4(200/26) | 4×25 | 22.5 | 1079 |

| 16(30/30) | 2×1.5 | 9.0 | 96 | 2 (280/26) | 4×35 | 25.7 | 1506 |

| 14(50/30) | 2×2.5 | 9.9 | 122 | 1(400/26) | 4×50 | 30.1 | 2037 |

| 12(56/28) | 2×4 | 10.7 | 156 | 2/0(356/24) | 4×70 | 35.0 | 2804 |

| 10(84/28) | 2×6 | 11.8 | 202 | 3/0(485/24) | 4×95 | 40.2 | 3741 |

| 8(80/26) | 2×10 | 13.8 | 296 | 16(30/30) | 5G1.5 | 11.2 | 167 |

| 6(128/26) | 2×16 | 16.3 | 436 | 14(50/30) | 5G2.5 | 12.7 | 233 |

| 4(200/26) | 2×25 | 19.5 | 646 | 12(56/28) | 5G4 | 14.0 | 310 |

| 2 (280/26) | 2×35 | 22.5 | 880 | 10(84/28) | 5G6 | 16.0 | 431 |

| 16(30/30) | 3G1.5 | 9.6 | 117 | 8(80/26) | 5G10 | 18.1 | 619 |

| 14(50/30) | 3G2.5 | 11.2 | 172 | 6(128/26) | 5G16 | 21.5 | 928 |

| 12(56/28) | 3G4 | 12.0 | 216 | 4(200/26) | 5G25 | 25.7 | 1387 |

| 10(84/28) | 3G6 | 13.4 | 286 | 2 (280/26) | 5G35 | 29.8 | 1905 |

| 8(80/26) | 3G10 | 15.7 | 422 |