6381B

Application and Description

These cables are suitable for D.C. power supplies on telecom equipment and power applications where flexibility is required. The cables produce no corrosive gases when burnt which is important where electronic equipment is installed.

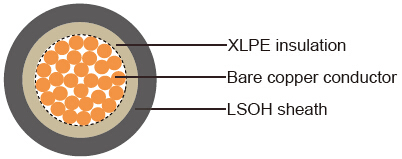

Cable Construction

- - Bare copper conductor

- - Stranding to BS6360 CL-5 or IEC60228 CL-5

- - XLPE(Cross-Linked Polyethylene) GP8 insulation

- - LSOH(Low Smoke Zero Halogen) LTS4 sheath

Sheath/Core Identification

- Blue (Blue), Grey (Grey), Green/Yellow (Green/Yellow), Brown (Brown), Special colours to order

Technical Characteristics

- - Working voltage: 600/1000V

- - Minimum bending radius: up to 50 mm^2 : 3xoverall diameter,

70mm^2 and above: - 4xoverall diameter - - Operating temperature: 0o C to +90o C

- - Insulation resistance: 10 MΩxkm

- - Flame retardant: IEC 60332.1, BS4066 Part 1

Cable Parameter

| AWG (No of Strands/ Strand Diameter) |

No. of Cores x Nominal Cross Sectional Area #xmm^2 |

Nominal Thickness of Insulation mm |

Nominal Thickness of Sheath mm |

Nominal Overall Diameter mm |

Nominal Weight kg/km |

| 16(30/30) | 1x1.5 | 0.9 | 0.8 | 5.2 | 42 |

| 14(50/30) | 1x2.5 | 0.9 | 0.8 | 5.7 | 54 |

| 12(56/28) | 1x4 | 1 | 0.9 | 6.6 | 77 |

| 10(84/28) | 1x6 | 1.1 | 0.9 | 7.3 | 102 |

| 8(80/26) | 1x10 | 1.2 | 1 | 8.6 | 160 |

| 6(128/26) | 1x16 | 1.2 | 1 | 9.6 | 210 |

| 4(200/26) | 1x25 | 1.4 | 1.1 | 11.5 | 320 |

| 2(280/26) | 1x35 | 1.4 | 1.1 | 12.8 | 420 |

| 1(400/26) | 1x50 | 1.4 | 1.4 | 14.9 | 590 |

| 2/0(356/24) | 1x70 | 1.4 | 1.4 | 17.2 | 810 |

| 3/0(485/24) | 1x95 | 1.6 | 1.5 | 18.6 | 1020 |

| 4/0(614/24) | 1x120 | 1.6 | 1.8 | 20.8 | 1285 |

| 300MCM (765/24) | 1x150 | 1.8 | 1.8 | 23.1 | 1610 |

| 350MCM (944/24) | 1x185 | 2 | 1.8 | 25.3 | 1940 |

| 500MCM(1225/24) | 1x240 | 2.2 | 1.8 | 27.8 | 2480 |

| -(1525/24) | 1x300 | 2.4 | 2 | 31.2 | 3050 |

| -(2013/24) | 1x400 | 2.6 | 2.1 | 35.3 | 4035 |

| -(1769/23) | 1x500 | 2.8 | 2.2 | 38.8 | 4970 |

| -(2257/23) | 1x630 | 2.8 | 2.4 | 43.8 | 6510 |