H07RN-F

Application and Description

These cables are designed to provide high flexibility and have the capacity to withstand weather, oils/greases, mechanical and thermal stresses.

Applications include handling quipment, mobile power supplies, worksites, stage and audio visual equipment, port areas and dams. Also suitable for fixed installations on plaster, temporary buildings and residential barracks and for use in drainage and water treatment, cold environments and severe industrial environments.

These cables are resistant to flame, acids, and oil penetration.

Standard and Approval

- NF C 32-102-4,EN 50525-2-21,EN 60332-1/NF C 32-070 2.1(C2),EN 50575(Eca),CE Approval

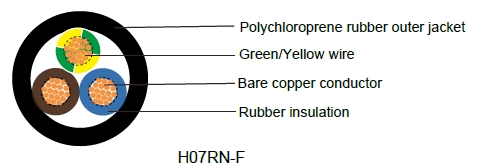

Cable Construction

| Fine bare copper strands |

| Strands to IEC/EN 60228 Class-5 |

| Rubber core insulation |

| Color code to XP C32-321 |

| Polychloroprene rubber (neoprene) jacket |

Technical Characteristics

| Working voltage |

450/750 volts |

| Test voltage |

2500 volts |

| Minimum bending radius |

6 x O |

| Operation temperature range |

-25o C to +60oC |

| Short circuit temperature |

+200 oC |

| Flame retardant |

EN 60332.1/NF C 32-070 C2 |

Cable Parameter

| AWG |

No. of Cores x Nominal Cross Sectional Area |

Nominal Thickness of Insulation |

Nominal Thickness of Sheath |

Nominal Overall Diameter |

Approx. Copper Weight |

Approx. Weight |

| |

# x mm^2 |

mm |

mm |

mm(min-max) |

kg/km |

kg/km |

| 17(32/32) |

2 x 1 |

0.8 |

1.3 |

7.7-10 |

19 |

89 |

| 17(32/32) |

3 x 1 |

0.8 |

1.4 |

8.3-10.7 |

29 |

111 |

| 17(32/32) |

4 x 1 |

0.8 |

1.5 |

9.2-11.9 |

38 |

146 |

| 16(30/30) |

1 x 1.5 |

0.8 |

1.4 |

5.7-7.1 |

14.4 |

59 |

| 16(30/30) |

2 x 1.5 |

0.8 |

1.5 |

8.5-11.0 |

29 |

135 |

| 16(30/30) |

3 x 1.5 |

0.8 |

1.6 |

9.2-11.9 |

43 |

165 |

| 16(30/30) |

4 x 1.5 |

0.8 |

1.7 |

10.2-13.1 |

58 |

200 |

| 16(30/30) |

5 x 1.5 |

0.8 |

1.8 |

11.2-14.4 |

72 |

240 |

| 16(30/30) |

7 x 1.5 |

0.8 |

2.6 |

14.5-17.5 |

101 |

385 |

| 16(30/30) |

12 x 1.5 |

0.8 |

2.9 |

17.6-22.4 |

173 |

516 |

| 16(30/30) |

19 x 1.5 |

0.8 |

3.2 |

20.7-26.3 |

274 |

800 |

| 16(30/30) |

24 x 1.5 |

0.8 |

3.5 |

24.3-30.7 |

346 |

882 |

| 14(50/30) |

1 x 2.5 |

0.9 |

1.4 |

6.3-7.9 |

24 |

72 |

| 14(50/30) |

2 x 2.5 |

0.9 |

1.7 |

10.2-13.1 |

48 |

195 |

| 14(50/30) |

3 x 2.5 |

0.9 |

1.8 |

10.9-14.0 |

72 |

235 |

| 14(50/30) |

4 x 2.5 |

0.9 |

1.9 |

12.1-15.5 |

96 |

290 |

| 14(50/30) |

5 x 2.5 |

0.9 |

2 |

13.3-17.0 |

120 |

345 |

| 14(50/30) |

7 x 2.5 |

0.9 |

2.8 |

16.5-20.0 |

168 |

520 |

| 14(50/30) |

12 x 2.5 |

0.9 |

3.1 |

20.6-26.2 |

288 |

810 |

| 14(50/30) |

19 x 2.5 |

0.9 |

3.5 |

25.5-31.0 |

456 |

1200 |

| 14(50/30) |

24 x 2.5 |

0.9 |

3.9 |

28.8-36.4 |

576 |

1650 |

| 12(56/28) |

1 x 4 |

1 |

1.5 |

7.2-9.0 |

38 |

99 |

| 12(56/28) |

2 x 4 |

1 |

1.8 |

11.8-15.1 |

77 |

270 |

| 12(56/28) |

3 x 4 |

1 |

1.9 |

12.7-16.2 |

115 |

320 |

| 12(56/28) |

4 x 4 |

1 |

2 |

14.0-17.9 |

154 |

395 |

| 12(56/28) |

5 x 4 |

1 |

2.2 |

15.6-19.9 |

192 |

485 |

| 12(56/28) |

7 x 4 |

1 |

3.1 |

18.2-21.8 |

269 |

681 |

| 10(84/28) |

1 x 6 |

1 |

1.6 |

7.9-9.8 |

58 |

130 |

| 10(84/28) |

3 x 6 |

1 |

2.1 |

14.1-18.0 |

173 |

495 |

| 10(84/28) |

4 x 6 |

1 |

2.3 |

15.7-20.0 |

230 |

610 |

| 10(84/28) |

5 x 6 |

1.2 |

3.6 |

17.5-22.2 |

288 |

760 |

| 8(80/26) |

1 x 10 |

1.2 |

1.8 |

9.5-11.9 |

96 |

230 |

| 8(80/26) |

3 x 10 |

1.2 |

3.3 |

19.1-24.2 |

288 |

880 |

| 8(80/26) |

4 x 10 |

1.2 |

3.4 |

20.9-26.5 |

384 |

1060 |

| 8(80/26) |

5 x 10 |

1.2 |

3.6 |

22.9-29.1 |

480 |

1300 |

| 6(128/26) |

1 x 16 |

1.2 |

1.9 |

10.8-13.4 |

154 |

320 |

| 6(128/26) |

3 x 16 |

1.2 |

3.5 |

21.8-27.6 |

461 |

1090 |

| 6(128/26) |

4 x 16 |

1.2 |

3.6 |

23.8-30.1 |

614 |

1345 |

| 6(128/26) |

5 x 16 |

1.2 |

3.9 |

26.4-33.3 |

768 |

1680 |

| 4(200/26) |

1 x25 |

1.4 |

2 |

12.7-15.8 |

240 |

450 |

| 4(200/26) |

4 x 25 |

1.4 |

4.1 |

28.9-36.6 |

960 |

1995 |

| 4(200/26) |

5 x 25 |

1.4 |

4.4 |

32.0-40.4 |

1200 |

2470 |

| 2(280/26) |

1 x 35 |

1.4 |

2.2 |

14.3-17.9 |

336 |

605 |

| 2(280/26) |

3 x 35 |

1.4 |

4.1 |

29.3-37.1 |

1008 |

1900 |

| 2(280/26) |

4 x 35 |

1.4 |

4.4 |

32.5-41.1 |

1344 |

2645 |

| 2(280/26) |

5 x 35 |

1.4 |

4.7 |

37.0-45.0 |

1680 |

2810 |

| 1(400/26) |

1 x 50 |

1.6 |

2.4 |

16.5-20.6 |

480 |

825 |

| 1(400/26) |

4 x 50 |

1.6 |

4.8 |

37.7-47.5 |

1920 |

3635 |

| 1(400/26) |

5 x 50 |

1.6 |

5.1 |

40.0-50.8 |

2400 |

4050 |

| 2/0(356/24) |

1 x 70 |

1.6 |

2.6 |

18.6-23.3 |

672 |

1090 |

| 2/0(356/24) |

4 x 70 |

1.6 |

5.2 |

42.7-54.0 |

2688 |

4830 |

| 3/0(485/24) |

1 x 95 |

1.8 |

2.8 |

20.8-26.0 |

912 |

1405 |

| 3/0(485/24) |

4 x 95 |

1.8 |

5.9 |

48.4-61.0 |

3648 |

6320 |

| 4/0(614/24) |

1x 120 |

1.8 |

3 |

22.8-28.6 |

1152 |

1746 |

| 4/0(614/24) |

4 x 120 |

1.8 |

6 |

53.0-66.0 |

4608 |

6830 |

| 300MCM (765/24) |

1 x 150 |

2 |

3.2 |

25.2-31.4 |

1440 |

1887 |

| 300MCM (765/24) |

4 x 150 |

2 |

6.4 |

58.0-73.0 |

5760 |

8320 |

| 350MCM (944/24) |

1 x 185 |

2.2 |

3.4 |

27.6-34.4 |

1776 |

2274 |

| 350MCM (944/24) |

4 x 185 |

2.2 |

6.8 |

64.0-80.0 |

7104 |

9800 |

| 500MCM (1221/24) |

1x 240 |

2.4 |

3.5 |

30.6-38.3 |

23.4 |

2956 |

| 500MCM (1221/24) |

4x 240 |

2.4 |

7.0 |

72.0-90.0 |

9216 |

12100 |

| - |

1 x 300 |

2.6 |

3.6 |

33.5-41.9 |

2880 |

3479 |