U-1000 ARVFV

Application and Description

With a sheath and armor, U-1000 ARVFV is an enhanced version of the cables and U-1000 AR2V. They can be used in all industrial installations requiring mechanical protection.

These cables can be provided in hard and SH C1 (NF C 32-323) and HR (resistant to aliphatic hydrocarbons). The design and characteristics of the materials comply with IEC 60502-1.

Standard and Approval

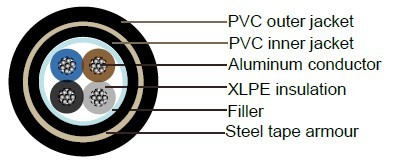

Cable Construction

| Aluminum conductor |

| Strands to IEC 60228 class 2 |

| XLPE insulation according to XP C 32-321 |

| Color codes to HD 308 S2(XP C32-321) |

| Not fibrous and not hygroscopic filler(only for multicore cables) |

| PVC inner jacket |

| Two steel tapes helically wraped armour |

| Flexible black PVC outer jacket |

Technical Characteristics

| Working Voltage |

600/1000 volts |

| Test voltage |

3500 volts |

| Minimum bending radius |

10 x O |

| Operation temperature rage |

-15 °C to 90 °C |

| Short-circuit temperature |

250 °C |

| Flame retardant |

EN 60332-1/NF C 32-070 C2 |

Cable Parameter

| AWG |

Cross Section |

Insulation thickness |

Amour thickness |

Minimum Sheath thickness |

Maximum Overall diameter |

Approx Cable weight |

| |

mm^2 |

mm |

mm |

mm |

mm |

kg/km |

| 8 |

2x10 |

0.7 |

0.2 |

1.4 |

18.5 |

420 |

| 6 |

2x16 |

0.7 |

0.2 |

1.5 |

20.5 |

540 |

| 4 |

2x25 |

0.9 |

0.2 |

1.6 |

24.5 |

760 |

| 2 |

2x35 |

0.9 |

0.2 |

1.7 |

27 |

930 |

| 8 |

3x10 |

0.7 |

0.2 |

1.5 |

19 |

470 |

| 6 |

3x16 |

0.7 |

0.2 |

1.5 |

22 |

590 |

| 4 |

3x25 |

0.9 |

0.2 |

1.6 |

26 |

830 |

| 2 |

3x35 |

0.9 |

0.2 |

1.7 |

29 |

1030 |

| 1 |

3x50 |

0.9 |

0.2 |

1.8 |

32.5 |

1290 |

| 2/0 |

3x70 |

1.1 |

0.2 |

2 |

37.5 |

1710 |

| 3/0 |

3x95 |

1.1 |

0.5 |

2.1 |

43.5 |

2610 |

| 4/0 |

3x120 |

1.2 |

0.5 |

2.3 |

47.5 |

3110 |

| 300MCM |

3x150 |

1.4 |

0.5 |

2.4 |

53 |

3770 |

| 500MCM |

3x185 |

1.6 |

0.5 |

2.5 |

58 |

4540 |

| 750MCM |

3x240 |

1.7 |

0.5 |

2.7 |

65.5 |

5620 |

| - |

3x300 |

1.8 |

0.5 |

2.9 |

72 |

6830 |

| 1 |

3x50+35 |

1.0/09 |

0.2 |

1.9 |

34.5 |

1500 |

| 2/0 |

3x70+50 |

1.1/0.9 |

0.2 |

2 |

40 |

2000 |

| 3/0 |

3x95+50 |

1.1/1.0 |

0.5 |

2.2 |

45 |

2870 |

| 4/0 |

3x120+70 |

1.2/1.1 |

0.5 |

2.3 |

50 |

3460 |

| 300MCM |

3x150+70 |

1.4/1.1 |

0.5 |

2.5 |

54 |

4090 |

| 500MCM |

3x185+70 |

1.6/1.1 |

0.5 |

2.6 |

59 |

4980 |

| 750MCM |

3x240+95 |

1.7/1.1 |

0.5 |

2.8 |

66 |

6210 |

| 8 |

4x10 |

0.7 |

0.2 |

1.5 |

20.5 |

540 |

| 6 |

4x16 |

0.7 |

0.2 |

1.6 |

23.5 |

700 |

| 4 |

4x25 |

0.9 |

0.2 |

1.7 |

28 |

1000 |

| 2 |

4x35 |

0.9 |

0.2 |

1.8 |

31.5 |

1230 |

| 1 |

4x50 |

1 |

0.2 |

1.9 |

35.5 |

1550 |

| 2/0 |

4x70 |

1.1 |

0.5 |

2.1 |

42.5 |

2490 |

| 3/0 |

4x95 |

1.1 |

0.5 |

2.3 |

47.5 |

3120 |

| 4/0 |

4x120 |

1.2 |

0.5 |

2.4 |

53 |

3780 |

| 300MCM |

4x150 |

1.4 |

0.5 |

2.6 |

58.5 |

4550 |

| 500MCM |

4x185 |

1.6 |

0.5 |

2.7 |

64.5 |

5490 |

| 750MCM |

4x240 |

1.7 |

0.5 |

2.9 |

72.5 |

6860 |

| - |

4x300 |

1.8 |

0.5 |

3.1 |

79.5 |

8250 |

| 8 |

5x10 |

0.7 |

0.2 |

1.6 |

22.5 |

640 |

| 6 |

5x16 |

0.7 |

0.2 |

1.8 |

26 |

820 |

| 4 |

5x25 |

0.9 |

0.2 |

1.8 |

31 |

1190 |