N2XY

Application and Description

N2XY power cables with insulation of cross-linked polyethylene (XLPE) are designed for distribution and supply of consumers with nominal voltage 0.6/1 kV and frequency 50 Hz in industrial installations and urban networks. They are suitable for fixed indoor assembly in cable ducts and conduits, over shelves and grilles, directly underground in ditch and outdoor under shelters providing the conditions determined for the type of cable.

Standard and Approval

VDE-0276 Part-603, HD 603.1, IEC 60502, VDE 0482-332-1-2, DIN EN 60332-1-2 / IEC 60332-1, CE Low Voltage Directive 73/23/EEC and 93/68/EEC, ROHS compliant

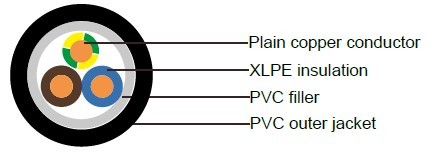

Cable Construction

- Solid or stranded, plain copper conductor

- to DIN VDE 0295 cl. 1 or cl. 2, BS 6360 cl. 1 or cl. 2 and IEC 60228 cl. 1 or cl. 2

- XLPE insulation type DIX3 acc. to VDE 0276-603/5G

- Color coded to DIN VDE 0293(HD 308)

- PVC filler

- PVC outer jacket DMV6 to HD 603.1

Technical Characteristics

- Working voltage: 600/1000 volts

- Test voltage: 4000 volts

- Minimum bending radius: 15 x O

- Flexing temperature: -5o C to +70o C

- Fixed installation temperature: - 30o C to +70o C

- Short circuit temperature: +250o C

- Flame retardant: IEC 60332.1

- Insulation resistance: >20 MΩ x km

Cable Parameter

| AWG | NO. OF CORES X NOMINAL CROSS SECTIONAL AREA # X MM^2 |

CONDUCTOR TYPE |

THICKNESS OF INSULATION MM | THICKNESS OF SHEATH MM | NOMINAL OVERALL DIAMETER MM |

COPPER WEIGHT KG / KM | CABLE WEIGHT KG / KM |

| 6 | 1x16 | rm | 0.7 | 1.8 | 11.0 | 144 | 230 |

| 4 | 1x25 | rm | 0.9 | 1.8 | 12.5 | 228 | 340 |

| 2 | 1x35 | rm | 0.9 | 1.8 | 13.5 | 317 | 445 |

| 1 | 1x50 | rm | 1.0 | 1,8 | 15.5 | 454 | 605 |

| 2/0 | 1x70 | rm | 1.1 | 1.8 | 17.0 | 656 | 800 |

| 3/0 | 1x95 | rm | 1.1 | 1.8 | 19.0 | 911 | 1065 |

| 4/0 | 1x120 | rm | 1.2 | 1.8 | 21.0 | 1147 | 1320 |

| 300mcm | 1x150 | rm | 1.4 | 1.8 | 23.0 | 1415 | 1610 |

| 350mcm | 1x185 | rm | 1.6 | 1.8 | 25.5 | 1770 | 1925 |

| 500mcm | 1x240 | rm | 1.7 | 1.8 | 28.5 | 2327 | 2483 |

| 750mcm | 1x300 | rm | 1.8 | 1.8 | 31.0 | 2887 | 3058 |

| - | 1x400 | rm | 2.0 | 1.9 | 35.0 | 3692 | 3887 |

| - | 1x500 | rm | 2.2 | 2.0 | 38.5 | 4725 | 4937 |

| 6 | 2x16 | rm | 0.7 | 1.8 | 19.5 | 294 | 645 |

| 4 | 2x25 | rm | 0.9 | 1.8 | 23.0 | 466 | 945 |

| 2 | 2x35 | rm | 0.9 | 2.0 | 25.5 | 646 | 1235 |

| 1 | 2x50 | rm | 1.0 | 2.0 | 29.0 | 924 | 1680 |

| 6 | 3x16 | rm | 0.7 | 1.8 | 20.5 | 441 | 805 |

| 4 | 3x25 | rm | 0.9 | 2.0 | 24.5 | 699 | 1220 |

| 2 | 3x35 | rm | 0.9 | 2.0 | 27.0 | 969 | 1575 |

| 1 | 3x50 | sm | 1.0 | 2.0 | 24.5 | 1387 | 1765 |

| 2/0 | 3x70 | sm | 1.1 | 2.0 | 28.0 | 1897 | 2350 |

| 3/0 | 3x95 | sm | 1.1 | 2.0 | 31.0 | 2631 | 3145 |

| 4/0 | 3x120 | sm | 1.2 | 2.0 | 34.0 | 3324 | 3915 |

| 300mcm | 3x150 | sm | 1.4 | 2.2 | 37.0 | 4084 | 4820 |

| 350mcm | 3x185 | sm | 1.6 | 2.2 | 42.0 | 5123 | 6045 |

| 500mcm | 3x240 | sm | 1.7 | 2.6 | 47.5 | 6733 | 7885 |

| 12 | 3x4.0+2.5 | re | 0.7/0.7 | 1.8 | 13.5 | 135 | 328 |

| 10 | 3x6.0+4 | re | 0.7/0.7 | 1.8 | 15.0 | 205 | 445 |

| 8 | 3x10+6 | re | 0.7/0.7 | 1.8 | 17.0 | 338 | 611 |

| 6 | 3x16+10 | re | 0.7/0.7 | 1.8 | 20. | 541 | 868 |

| 4 | 3x25+16 | rm | 0.9/0.7 | 2.0 | 27.0 | 846 | 1405 |

| 2 | 3x35+16 | rm | 0.9/0.7 | 2.0 | 29.5 | 1116 | 1765 |

| 1 | 3x50+25 | sm/rm | 1.0/0.9 | 2.0 | 28.5 | 1620 | 2075 |

| 2/0 | 3x70+35 | sm/rm | 1.1/0.9 | 2.0 | 33.0 | 2220 | 2650 |

| 3/0 | 3x95+50 | sm/rm | 1.1/1.0 | 2.2 | 36.5 | 3093 | 3615 |

| 4/0 | 3x120+70 | sm/rm | 1.2/1.1 | 2.2 | 39.0 | 3956 | 4690 |

| 300mcm | 3x150+70 | sm/rm | 1.4/1.1 | 2.2 | 44.0 | 4716 | 5630 |

| 350mcm | 3x185+95 | sm/rm | 1.6/1.1 | 2.6 | 48.5 | 6000 | 7150 |

| 500mcm | 3x240+120 | sm/rm | 1.7/1.2 | 3.0 | 57.0 | 7841 | 9305 |

| 6 | 4x16 | rm | 0.7 | 1.8 | 22.0 | 588 | 985 |

| 4 | 4x25 | rm | 0.9 | 2.0 | 27.0 | 932 | 1500 |

| 2 | 4x35 | rm | 0.9 | 2.0 | 29.5 | 1292 | 1955 |

| 1 | 4x50 | sm | 1.0 | 2.0 | 28.5 | 1850 | 2320 |

| 2/0 | 4x70 | sm | 1.1 | 2.0 | 33.0 | 2530 | 3100 |

| 3/0 | 4x95 | sm | 1.1 | 2.2 | 36.5 | 3508 | 4180 |

| 4/0 | 4x120 | sm | 1.2 | 2.2 | 39.0 | 4433 | 5200 |

| 300mcm | 4x150 | sm | 1.4 | 2.2 | 44.0 | 5446 | 6410 |

| 350mcm | 4x185 | sm | 1.6 | 2.6 | 48.5 | 6831 | 8050 |