NHXMH/(N)HXMH(St)

Application and Description

NHXMH cable is halogen free intended for fixed installation in dry and moist rooms as well as in masonry and concrete, in and under plaster; not for underground installation. NHXMH-J/O are especially used in buildings with a high concentration of persons or valuable property, where improved fire characteristics are needed. This product conforms to 73/23/EW G directive (low voltage directive) CE.

Standard and Approval

VDE 0250 (part 214), VDE 0482 (part 266-2-4, test type C), IEC 60228; IEC 60332-3-22; IEC 60754-1; IEC 60754-2, IEC 61034

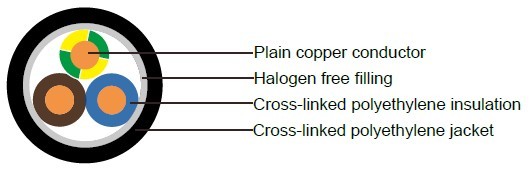

Cable Construction

- Plain copper conductor, single conductor up to 10 mm^2 multi-conductor from 16-35 mm^2

- To DIN VDE 0295 cl. 1 or 2, BS 6360 cl. 1 or 2 and IEC 60228 cl. 1 or 2

- Cross-linked polyethylene compound insulation 2XI1 to DIN VDE 0207 part 22

- Color coded to DIN VDE 0293-308

- Green-yellow grounding (3 conductors and above)

- Halogen free filling compound (not for single core cables)

- Flame-retardant, halogen free polyethylene compound jacket HM2 according to DIN VDE 0207 part 2

Technical Characteristics

- Working voltage: 300/500 volts

- Test voltage: 2000 volts

- Minimum bending radius: single conductor 15 x O

- Minimum bending radius: multi conductor 12 x O

- Flexing temperature: -5o C to +50o C

- Fixed installation temperature: - 30o C to +70o C

- Short circuit temperature: +250o C

- Flame-retardant to DIN VDE 0482 part 266-2/HD 405.3/BS 4066 PT3/EN 50266-2/IEC 60332-3

- Low corrosiveness of combustion gases

to DIN VDE 0482 part 267/BS 6425 PT2/EN 50267-2-2/IEC 60754-2

- Halogen-free to DIN VDE 0482 part 267/BS 6425 PT1/EN 50267-2-1/IEC 60754-1

- Smoke density to DIN VDE 0482 part 268/HD 606/BS 7622 PT1,PT2/EN 50268-1,-2/IEC 61034-1,-2

- Insulation resistance: >100 MΩ x km

Cable Parameter

| AWG | NO. OF CORES X NOMINAL CROSS SECTIONAL AREA # X MM^2 |

STRANDED CONDUCTOR TYPE | NOMINAL OVERALL DIAMETER MM |

NOMINAL COPPER WEIGHT KG/KM | NOMINAL CABLE WEIGHT KG/KM |

| 16 | 1 x 1.5 | re | 7 | 15 | 49 |

| 14 | 1 x 2.5 | re | 7.6 | 24 | 60 |

| 12 | 1 x 4.0 | re | 8.6 | 39 | 80 |

| 10 | 1 x 6.0 | re | 9.9 | 58 | 111 |

| 8 | 1 x 10.0 | re | 11.2 | 96 | 160 |

| 6 | 1 x 16.0 | re | 11.9 | 154 | 232 |

| 16 | 2 x 1.5 | re | 8.9 | 29 | 110 |

| 14 | 2 x 2.5 | re | 10 | 48 | 136 |

| 12 | 2 x 4.0 | re | 11.4 | 77 | 202 |

| 16 | 3 x 1.5 | re | 9.4 | 43 | 130 |

| 14 | 3 x 2.5 | re | 10.4 | 72 | 163 |

| 12 | 3 x 4.0 | re | 11.8 | 115 | 235 |

| 10 | 3 x 6.0 | re | 13.4 | 173 | 323 |

| 8 | 3 x 10.0 | re | 16 | 288 | 485 |

| 6 | 3 x 16.0 | re | 19.7 | 461 | 850 |

| 4 | 3 x 25.0 | rm | 24.3 | 720 | 1152 |

| 2 | 3 x 35.0 | sm | 27.2 | 1008 | 1503 |

| 16 | 4 x 1.5 | re | 10.2 | 58 | 151 |

| 14 | 4 x 2.5 | re | 11.3 | 96 | 200 |

| 12 | 4 x 4.0 | re | 13.3 | 154 | 300 |

| 10 | 4 x 6.0 | re | 14.8 | 230 | 400 |

| 8 | 4 x 10.0 | re | 17.4 | 384 | 603 |

| 6 | 4 x 16.0 | re | 21.6 | 615 | 940 |

| 4 | 4 x 25.0 | rm | 27 | 960 | 1432 |

| 2 | 4 x 35.0 | sm | 29.9 | 1344 | 1930 |

| 16 | 5 x 1.5 | re | 10.8 | 72 | 177 |

| 14 | 5 x 2.5 | re | 11.9 | 120 | 238 |

| 12 | 5 x 4.0 | re | 14.8 | 192 | 345 |

| 10 | 5 x 6.0 | re | 16 | 288 | 475 |

| 8 | 5 x 10.0 | re | 18.9 | 480 | 720 |

| 6 | 5 x 16.0 | re | 23.8 | 768 | 1142 |

| 4 | 5 x 25.0 | rm | 29 | 1200 | 1800 |

| 2 | 5 x 35.0 | rm | 32.7 | 1680 | 2490 |

| 16 | 7 x 1.5 | re | 11.4 | 101 | 209 |

| 14 | 7 x 2.5 | re | 13.5 | 168 | 300 |