Portable Welding Cable 600V

Applications

These cables are designed for useas flexible welding leads connecting the electrode holder to thewelding machine in the secondary circuit of electric arc welding systems.

Standards

- ICEA S-75-381/NEMA WC 58

- ASTM B 172

- ASTM B 33

- CAN/CSA C22.2 No. 96

- UL 1581

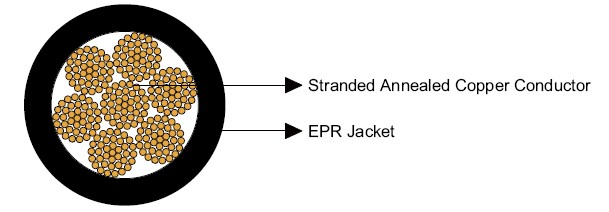

Construction

- Conductors: Class K/M stranded annealed copper conductor.

- Sheath:EPR. Other sheath materials can be offered as an option.

Options

Other jacket materials such as CSP/PCP/NBR/PVC are available upon request.

Two-layer jacket with reinforcing fibre between the two layers can be offered as an option.

Mechanical and Thermal Properties

- Minimum Bending Radius: 6×OD

- Maximum Operating Temperature: +90℃

Dimensions and Weight

Construction |

No. of Strands |

Nominal Insulation Thickness |

Nominal Overall Diameter |

Nominal Weight |

Ampacity |

|||

No. of cores×AWG/kcmil |

- |

inch |

mm |

inch |

mm |

lbs/kft |

kg/km |

A |

1×6 |

259 |

0.060 |

1.5 |

0.37 |

9.4 |

124 |

184 |

125 |

1×4 |

420 |

0.060 |

1.5 |

0.42 |

10.7 |

180 |

268 |

182 |

1×2 |

665 |

0.060 |

1.5 |

0.49 |

12.5 |

268 |

399 |

271 |

1×1 |

836 |

0.080 |

2.0 |

0.53 |

13.3 |

319 |

475 |

360 |

1×1/0 |

1045 |

0.080 |

2.0 |

0.59 |

14.9 |

415 |

617 |

444 |

1×2/0 |

1330 |

0.080 |

2.0 |

0.64 |

16.3 |

508 |

756 |

535 |

1×3/0 |

1672 |

0.080 |

2.0 |

0.70 |

17.8 |

628 |

934 |

667 |

1×4/0 |

2107 |

0.080 |

2.0 |

0.81 |

20.7 |

775 |

1153 |

809 |

1×250 |

2499 |

0.095 |

2.4 |

0.88 |

22.4 |

934 |

1390 |

1048 |

1×350 |

3458 |

0.095 |

2.4 |

1.01 |

25.6 |

1267 |

1885 |

1396 |

1×500 |

5054 |

0.095 |

2.4 |

1.18 |

30.0 |

1801 |

2680 |

1973 |