| FIREGUARD Flame Retardant Cables | |||

![]() Flame Retardant Power & Control Cables

Flame Retardant Power & Control Cables

600/1000V XLPE Insulated, PVC Sheathed, Armoured Power Cables (Single Core)FGD300 1RCVMV-R (CU/XLPE/CUTO/PVC/AWA/PVC 600/1000V Class 2) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flame Retardance (Single Vertical |

EN 60332-1-2; IEC 60332-1-2; BS EN 60332-1-2; VDE |

Reduced Fire Propagation |

EN 60332-3-24 (cat. C); IEC 60332-3-24; BS EN 60332-3-24; VDE 0482-332-3; NBN C 30-004 (cat. F2); NF C32-070-2.2(C1); CEI 20-22/3-4; EN 50266-2-4*; DIN VDE 0482-266-2-4 |

Note: Asterisk ** denotes that the standard compliance is optional, depending on the oxygen index of the PVC

compound and the cable design.

VOLTAGE RATING

600/1000V

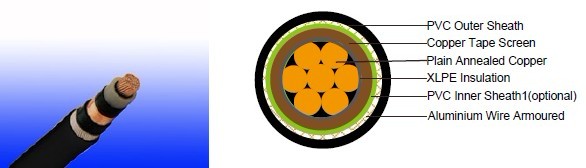

CABLE CONSTRUCTION

Conductor: Plain annealed copper wire, stranded according to IEC(EN) 60228 class 2.

Insulation: Extruded cross-linked XLPE compound.

Overall Screen: Copper Tape

Inner sheath: PVC Compound

Outer Sheath: Thermoplastic PVC compound. UV resistance, hydrocarbon resistance, oil resistance,

anti rodent and anti termite properties can be offered as option. Compliance to fire performance

standard (IEC 60332-1, IEC 60332-3, UL 1581, UL 1666 etc) depends on the oxygen index of the

PVC compound and the overall cable design. LSPVC can also be provided upon request.

COLOUR CODE

Insulation Colour as per BS7671

|

With Earth Conductor |

Without Earth Conductor |

2Cores |

- |

Brown, Blue |

3Cores |

Yellow/Green, Brown, Blue |

Brown, Gray, Black |

4Cores |

Yellow/Green, Brown, Gray, Black |

Brown, Gray, Black, Blue |

5Cores |

Yellow/Green, Brown, Gray, Black, Blue |

Brown, Gray, Black, Blue, Black |

Above 5 Cores |

Yellow/Green, Black Numbered |

Black Numbered |

Sheath Colour: Black (other colors upon request)

Physical AND THERMAL PROPERTIES

Maximum conductor temperature: Max 90°C for XLPE

Minimum bending radius: 12 x Overall Diameter (for 70mm2 to 1000mm2)

CONSTRUCTION PARAMETERS

Conductor |

FGD300 1RCVMV-R |

|||||||

No. of Core |

No./ Nominal Diameter of |

Nominal Insulation Thickness |

Nominal Sheath Thickness |

Diameter Under Screen |

Diameter Over Inner Sheath |

Armour Wire Diameter |

Nominal Overall Diameter |

Approx. Weight |

mm2 |

No./mm |

mm |

mm |

mm |

mm |

mm |

mm |

kg/km |

1x70 |

19/2.14 |

1.1 |

1.8 |

15.2 |

17.6 |

20.1 |

23.9 |

1400 |

1x95 |

19/2.52 |

1.1 |

1.8 |

17.1 |

19.5 |

22.0 |

25.8 |

1700 |

1x120 |

37/2.03 |

1.2 |

1.8 |

19.0 |

20.8 |

24.0 |

27.8 |

2000 |

1x150 |

37/2.25 |

1.4 |

1.8 |

21.0 |

22.8 |

26.0 |

29.8 |

2400 |

1x185 |

37/2.52 |

1.6 |

1.8 |

23.2 |

25.0 |

28.2 |

32.0 |

2800 |

1x240 |

61/2.25 |

1.7 |

1.9 |

26.1 |

27.9 |

31.1 |

35.1 |

3500 |

1x300 |

61/2.52 |

1.8 |

2.0 |

28.7 |

30.5 |

33.7 |

37.9 |

4200 |

1x400 |

61/2.85 |

2.0 |

2.1 |

32.5 |

34.3 |

38.3 |

42.7 |

5400 |

1x500 |

61/3.20 |

2.2 |

2.2 |

36.0 |

37.8 |

41.8 |

46.4 |

6500 |

1x630 |

127/2.52 |

2.4 |

2.3 |

40.4 |

42.2 |

46.2 |

51.0 |

8200 |

1x800 |

127/2.85 |

2.6 |

2.5 |

45.5 |

47.3 |

52.3 |

57.5 |

10400 |

1x1000 |

127/3.20 |

2.8 |

2.7 |

50.4 |

52.2 |

57.2 |

62.4 |

13000 |

Electrical Properties

Conductor Operating Temperature : 90°C

Ambient Temperature : 30°C

Current-Carrying Capacities (Amp)

Conductor cross- sectional area |

Reference Method |

Reference Method |

Reference Method 12 (free air) |

In single-way ducts |

Laid direct in ground |

||||

|

2 cables, single- phase a.c. or d.c. |

3 or 4 cables, |

2 cables, single- phase a.c. or d.c. |

3 or 4 cables, |

3 cables |

2 cables, single- phase a.c. or d.c. |

3 or 4 cables, |

2 cables, single- phase a.c. or d.c. |

3 or 4 cables, |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

mm2 |

A |

A |

A |

A |

A |

A |

A |

A |

A |

70 |

303 |

277 |

322 |

293 |

285 |

310 |

280 |

340 |

290 |

95 |

367 |

333 |

389 |

352 |

346 |

365 |

330 |

405 |

345 |

120 |

425 |

383 |

449 |

405 |

402 |

410 |

370 |

460 |

389 |

150 |

488 |

437 |

516 |

462 |

463 |

445 |

405 |

510 |

435 |

185 |

557 |

496 |

587 |

524 |

529 |

485 |

440 |

580 |

490 |

240 |

656 |

579 |

689 |

612 |

625 |

550 |

500 |

670 |

560 |

300 |

755 |

662 |

792 |

700 |

720 |

610 |

550 |

750 |

630 |

400 |

853 |

717 |

899 |

767 |

815 |

640 |

580 |

830 |

700 |

500 |

962 |

791 |

1016 |

851 |

918 |

690 |

620 |

910 |

770 |

630 |

1082 |

861 |

1146 |

935 |

1027 |

750 |

670 |

1000 |

840 |

800 |

1170 |

904 |

1246 |

987 |

1119 |

828 |

735 |

1117 |

931 |

1000 |

1261 |

961 |

1345 |

1055 |

1214 |

919 |

811 |

1254 |

1038 |

Voltage Drop (Per Amp Per Meter)

| Conductor crosssectional area |

2 cables d.c. |

2 cables singlephase a.c. |

3 or 4 cables three-phase a.c. | 2 cables singlephase a.c. |

3 or 4 cables, 3-phase a.c. touching |

|||||||||

| Reference Method 1 & 11 (touching) |

Reference Method 1, 11 & 12 (in trefoil touching) |

Reference Method 1 & 11 (Flat touching) |

In ducts |

In ground |

In ducts |

In ground |

||||||||

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

||||||

mm2 |

mV/A/m |

mV/A/m |

mV/A/m |

mV/A/m |

mV/A/m |

mV/A/m |

mV/A/m |

mV/A/m |

||||||

|

|

r |

x |

z |

r |

x |

z |

r |

x |

z |

|

|

|

|

70 |

0.67 |

0.68 |

0.20 |

0.71 |

0.59 |

0.17 |

0.62 |

0.6 |

0.25 |

0.65 |

0.80 |

0.70 |

0.70 |

0.61 |

95 |

0.49 |

0.51 |

0.195 |

0.55 |

0.44 |

0.17 |

0.47 |

0.46 |

0.24 |

0.52 |

0.65 |

0.53 |

0.56 |

0.46 |

120 |

0.39 |

0.41 |

0.190 |

0.45 |

0.35 |

0.165 |

0.39 |

0.38 |

0.24 |

0.44 |

0.55 |

0.43 |

0.48 |

0.37 |

150 |

0.31 |

0.33 |

0.185 |

0.38 |

0.29 |

0.160 |

0.33 |

0.31 |

0.23 |

0.39 |

0.50 |

0.37 |

0.43 |

0.32 |

185 |

0.25 |

0.27 |

0.185 |

0.33 |

0.23 |

0.160 |

0.28 |

0.26 |

0.23 |

0.34 |

0.45 |

0.31 |

0.39 |

0.27 |

240 |

0.195 |

0.21 |

0.180 |

0.28 |

0.18 |

0.155 |

0.24 |

0.21 |

0.22 |

0.30 |

0.40 |

0.26 |

0.35 |

0.23 |

300 |

0.155 |

0.17 |

0.175 |

0.25 |

0.145 |

0.150 |

0.21 |

0.17 |

0.22 |

0.28 |

0.37 |

0.24 |

0.32 |

0.21 |

400 |

0.115 |

0.145 |

0.170 |

0.22 |

0.125 |

0.150 |

0.195 |

0.160 |

0.21 |

0.27 |

0.35 |

0.21 |

0.30 |

0.19 |

500 |

0.093 |

0.125 |

0.170 |

0.21 |

0.105 |

0.145 |

0.180 |

0.145 |

0.20 |

0.25 |

0.33 |

0.20 |

0.28 |

0.18 |

630 |

0.073 |

0.105 |

0.165 |

0.195 |

0.092 |

0.145 |

0.170 |

0.135 |

0.195 |

0.24 |

0.30 |

0.19 |

0.26 |

0.17 |

800 |

0.056 |

0.090 |

0.160 |

0.190 |

0.086 |

0.140 |

0.165 |

0.130 |

0.180 |

0.23 |

0.28 |

0.18 |

0.24 |

0.16 |

1000 |

0.045 |

0.092 |

0.155 |

0.180 |

0.080 |

0.135 |

0.155 |

0.125 |

0.170 |

0.21 |

0.26 |

0.17 |

0.22 |

0.15 |