| FIREGUARD Flame Retardant Cables | |||

![]() Flame Retardant Power & Control Cables

Flame Retardant Power & Control Cables

600/1000V PVC Insulated, Non-sheathed Power Cables (Single Core)FGD300 1V-R (CU/PVC 600/1000V Class 2) |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flame Retardance (Single Vertical |

EN 60332-1-2; IEC 60332-1-2; BS EN 60332-1-2; VDE |

Reduced Fire Propagation |

EN 60332-3-24 (cat. C); IEC 60332-3-24; BS EN 60332-3-24; VDE 0482-332-3; NBN C 30-004 (cat. F2); NF C32-070-2.2(C1); CEI 20-22/3-4; EN 50266-2-4*; DIN VDE 0482-266-2-4 |

Note: Asterisk ** denotes that the standard compliance is optional, depending on the oxygen index of the PVC

compound and the cable design.

VOLTAGE RATING

600/1000V

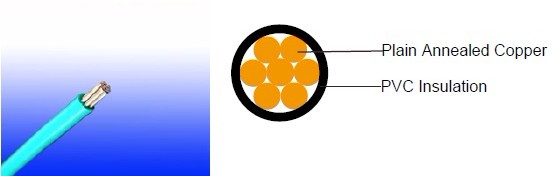

CABLE CONSTRUCTION

Conductor: Plain annealed copper wire, stranded according to IEC(EN) 60228 class 2.

Insulation: Thermoplastic PVC compound. UV resistance, hydrocarbon resistance, oil resistance,

anti rodent and anti termite properties can be offered as option. Compliance to fire performance

standard (IEC 60332-1, IEC 60332-3, UL 1581, UL 1666 etc) depends on the oxygen index of the

PVC compound and the overall cable design. LSPVC can also be provided upon request.

COLOUR CODE

Insulation Colour as per BS7671

|

With Earth Conductor |

Without Earth Conductor |

2Cores |

- |

Brown, Blue |

3Cores |

Yellow/Green, Brown, Blue |

Brown, Gray, Black |

4Cores |

Yellow/Green, Brown, Gray, Black |

Brown, Gray, Black, Blue |

5Cores |

Yellow/Green, Brown, Gray, Black, Blue |

Brown, Gray, Black, Blue, Black |

Above 5 Cores |

Yellow/Green, Black Numbered |

Black Numbered |

Sheath Colour: Black (other colors upon request)

Physical AND THERMAL PROPERTIES

Temperature range during operation: Max.90°C

250°C in short-circuit for 5secs max.

Minimum bending radius: 8 x Overall Diameter (unarmoured cable)

10 x Overall Diameter (armoured cable)

CONSTRUCTION PARAMETERS

| Conductor | FGD300 1V-R | |||

No. of Core X |

No./Nominal |

Nominal |

Insulated, Non-Sheathed | |

Nominal |

Approx. |

|||

Noxmm2 |

No./mm |

mm |

mm |

kg/km |

1x1.5 |

7/0.53 |

0.7 |

3.1 |

22 |

1x2.5 |

7/0.67 |

0.8 |

3.7 |

34 |

1x4 |

7/0.85 |

0.8 |

4.3 |

50 |

1x6 |

7/1.04 |

0.8 |

4.8 |

70 |

1x10 |

7/1.35 |

1.0 |

6.2 |

116 |

1x16 |

7/1.70 |

1.0 |

7.2 |

174 |

1x25 |

7/2.14 |

1.2 |

9.0 |

276 |

1x35 |

7/2.52 |

1.2 |

10.0 |

366 |

1x50 |

19/1.78 |

1.4 |

11.9 |

502 |

1x70 |

19/2.14 |

1.4 |

13.7 |

706 |

1x95 |

19/2.52 |

1.6 |

16.0 |

974 |

1x120 |

37/2.03 |

1.6 |

17.6 |

1213 |

1x150 |

37/2.25 |

1.8 |

19.6 |

1492 |

1x185 |

37/2.52 |

2.0 |

21.8 |

1868 |

1x240 |

61/2.25 |

2.2 |

24.4 |

2443 |

1x300 |

61/2.52 |

2.4 |

27.7 |

3055 |

1x400 |

61/2.85 |

2.6 |

31.1 |

3888 |

1x500 |

61/3.20 |

2.8 |

34.6 |

4880 |

1x630 |

127/2.52 |

2.8 |

38.6 |

6229 |

Electrical Properties

Conductor Operating Temperature : 90°C

Ambient Temperature : 30°C

Current-Carrying Capacities (Amp)

Conductor cross- sectional area |

Reference Method |

Reference |

Reference Method |

Reference Method 11 (on a perforated cable tray, horizontal or vertical) |

Reference Method 12 (free air) |

||||||

Horizontal flat spaced |

Vertical flat spaced |

Trefoil |

|||||||||

|

2 cables, single- phase a.c. or d.c. |

3 or 4 cables, |

2 cables, single- phase a.c. or d.c |

3 or 4 cables, |

2 cables, single- phase a.c. or d.c. flat and touching |

3 or 4 cables, |

2 cables, single- phase a.c. or d.c. or flat and touching |

3 or 4 cables, |

2 cables, single- phase a.c. or d.c. |

2 cables, |

3 cables, trefoil |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

mm2 |

A |

A |

A |

A |

A |

A |

A |

A |

A |

A |

A |

1.5 |

18 |

17 |

22 |

19 |

25 |

23 |

- |

- |

- |

- |

- |

2.5 |

24 |

23 |

30 |

26 |

34 |

31 |

- |

- |

- |

- |

- |

4 |

33 |

30 |

40 |

35 |

46 |

41 |

- |

- |

- |

- |

- |

6 |

43 |

39 |

51 |

45 |

59 |

54 |

- |

- |

- |

- |

- |

10 |

58 |

53 |

71 |

63 |

81 |

74 |

- |

- |

- |

- |

- |

16 |

76 |

70 |

95 |

85 |

109 |

99 |

- |

- |

- |

- |

- |

25 |

100 |

91 |

126 |

111 |

143 |

130 |

158 |

140 |

183 |

163 |

138 |

35 |

125 |

111 |

156 |

138 |

176 |

161 |

195 |

176 |

226 |

203 |

171 |

50 |

149 |

135 |

189 |

168 |

228 |

209 |

293 |

215 |

274 |

246 |

209 |

70 |

189 |

170 |

240 |

214 |

293 |

268 |

308 |

279 |

351 |

318 |

270 |

95 |

228 |

205 |

290 |

259 |

355 |

326 |

375 |

341 |

426 |

389 |

330 |

120 |

263 |

235 |

336 |

299 |

413 |

379 |

436 |

398 |

495 |

453 |

385 |

150 |

300 |

270 |

375 |

328 |

476 |

436 |

505 |

461 |

570 |

524 |

445 |

185 |

341 |

306 |

426 |

370 |

545 |

500 |

579 |

530 |

651 |

600 |

511 |

240 |

400 |

358 |

500 |

433 |

644 |

590 |

686 |

630 |

769 |

711 |

606 |

300 |

459 |

410 |

573 |

493 |

743 |

681 |

794 |

730 |

886 |

824 |

701 |

400 |

- |

- |

684 |

584 |

868 |

793 |

915 |

849 |

1065 |

994 |

820 |

500 |

- |

- |

783 |

666 |

990 |

904 |

1044 |

973 |

1228 |

1150 |

936 |

630 |

- |

- |

900 |

764 |

1130 |

1033 |

1191 |

1115 |

1423 |

1338 |

1069 |

Voltage Drop (Per Amp Per Meter)

| Size of conductor |

2 cables d.c. |

2 cables, single-phase a.c. | 3 or 4 cables, 3-phase a.c. | |||||||||||||

| Ref. Methods 3 and 4 (enclosed in conduit etc, in or on a wall) |

Ref. Methods 1 and 11 (clipped direct or on trays touching) |

Ref. Methods 3 and 4 (enclosed in conduit etc, in or on a wall) |

Ref. Methods 1, 11 and 12 (in trefoil) |

Ref. Methods 1 and 11 (Flat and touching) |

||||||||||||

1 |

2 |

3 |

4 |

5 |

6 |

7 |

||||||||||

mm2 |

mV/A/m |

mV/A/m |

mV/A/m |

mV/A/m |

mV/A/m |

mV/A/m |

||||||||||

1.5 |

31 |

31 |

27 |

27 |

27 |

27 |

||||||||||

2.5 |

19 |

19 |

16 |

16 |

16 |

16 |

||||||||||

4 |

33 |

12 |

10 |

10 |

10 |

10 |

||||||||||

6 |

7.8 |

7.9 |

6.8 |

6.8 |

6.8 |

6.8 |

||||||||||

10 |

4.7 |

4.7 |

4.7 |

4 |

4 |

4 |

||||||||||

16 |

2.9 |

2.9 |

2.9 |

2.5 |

2.5 |

2.5 |

||||||||||

|

|

r |

x |

z |

r |

x |

z |

r |

x |

z |

r |

x |

z |

r |

x |

z |

25 |

1.85 |

1.85 |

0.31 |

1.90 |

1.85 |

0.190 |

1.85 |

1.60 |

0.27 |

1.65 |

1.600 |

0.165 |

1.600 |

1.600 |

0.190 |

1.600 |

35 |

1.35 |

1.35 |

0.29 |

1.35 |

1.35 |

0.180 |

1.35 |

1.15 |

0.25 |

1.15 |

1.150 |

0.155 |

1.50 |

1.150 |

0.180 |

1.150 |

50 |

0.99 |

1.00 |

0.29 |

1.05 |

0.99 |

0.180 |

1.00 |

0.87 |

0.25 |

0.90 |

0.860 |

0.155 |

0.870 |

0.860 |

0.180 |

0.870 |

70 |

0.68 |

0.70 |

0.28 |

0.75 |

0.68 |

0.175 |

0.71 |

0.60 |

0.24 |

0.65 |

0.590 |

0.150 |

0.610 |

0.590 |

0.175 |

0.620 |

95 |

0.49 |

0.51 |

0.27 |

0.58 |

0.49 |

0.170 |

0.52 |

0.44 |

0.23 |

0.50 |

0.430 |

0.145 |

0.450 |

0.430 |

0.170 |

0.460 |

120 |

0.39 |

0.41 |

0.26 |

0.48 |

0.39 |

0.165 |

0.43 |

0.35 |

0.23 |

0.42 |

0.340 |

0.140 |

0.370 |

0.340 |

0.165 |

0.380 |

150 |

0.32 |

0.33 |

0.26 |

0.43 |

0.32 |

0.165 |

0.36 |

0.29 |

0.23 |

0.37 |

0.280 |

0.140 |

0.310 |

0.280 |

0.165 |

0.320 |

185 |

0.25 |

0.27 |

0.26 |

0.37 |

0.26 |

0.165 |

0.30 |

0.23 |

0.23 |

0.32 |

0.220 |

0.140 |

0.260 |

0.220 |

0.165 |

0.280 |

240 |

0.19 |

0.21 |

0.26 |

0.33 |

0.20 |

0.160 |

0.25 |

0.185 |

0.22 |

0.29 |

0.170 |

0.140 |

0.220 |

0.170 |

0.165 |

0.240 |

300 |

0.155 |

0.175 |

0.25 |

0.31 |

0.16 |

0.160 |

0.22 |

0.150 |

0.22 |

0.27 |

0.140 |

0.140 |

0.195 |

0.135 |

0.160 |

0.210 |

400 |

0.12 |

0.140 |

0.25 |

0.29 |

0.13 |

0.155 |

0.20 |

0.125 |

0.22 |

0.25 |

0.110 |

0.135 |

0.175 |

0.110 |

0.160 |

0.195 |

500 |

0.093 |

0.120 |

0.25 |

0.28 |

0.105 |

0.155 |

0.185 |

0.100 |

0.22 |

0.24 |

0.090 |

0.135 |

0.160 |

0.088 |

0.160 |

0.180 |

630 |

0.072 |

0.100 |

0.25 |

0.27 |

0.086 |

0.155 |

0.175 |

0.088 |

0.21 |

0.23 |

0.074 |

0.135 |

0.150 |

0.071 |

0.160 |

0.170 |