Multipair Individual/Overall Screen

Application

These cables are used in thermocouple circuits, petrochemical plants, utilities and industrial plants.

Specification

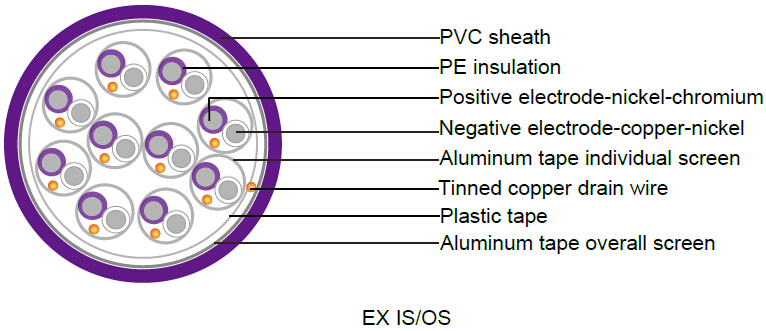

Conductor: Solid Type applicable: KX, EX, JX, TX, NX, KCA, KCB, RCA, RCB, SCA, RCB, BC

Insulation: PVC, PE, XLPE or LSZH thermoplastic material

Individual screen: 24 μm aluminium / PETP tape over solid tinned copper drain wire, 0.6 mm Wrapping: At least 1 layer of plastic tape

Overall screen: 24 μm aluminium / PETP tape over 7-stranded tinned copper drain wire, 0.5 mm²

Outer sheath: PVC or LSZH thermoplastic material

Color code: According to IEC 60584-3

Flame retardancy: IEC 60332-1

Flame propagation: IEC 60332 cat. C

Temperature range: -30°C up to 70°C during operation. -5°C up to 50°C during installation.

0.5 mm²

| Conductor Size (mm²) | No. of Pairs | Insulation Thickness (mm) | Outer Sheath Thickness (mm) | Nominal O.D. (mm) | Weight* (kg/km) |

| 0.5 | 2 | 0.4 | 1.0 | 9.1 | 83 |

| 0.5 | 4 | 0.4 | 1.0 | 10.4 | 132 |

| 0.5 | 6 | 0.4 | 1.2 | 12.8 | 196 |

| 0.5 | 8 | 0.4 | 1.2 | 13.6 | 244 |

| 0.5 | 10 | 0.4 | 1.2 | 15.3 | 300 |

| 0.5 | 12 | 0.4 | 1.2 | 16.0 | 346 |

| 0.5 | 16 | 0.4 | 1.4 | 18.5 | 459 |

| 0.5 | 20 | 0.4 | 1.4 | 20.3 | 555 |

| 0.5 | 24 | 0.4 | 1.4 | 21.9 | 659 |

0.8 mm²

| Conductor Size (mm²) | No. of Pairs | Insulation Thickness (mm) | Outer Sheath Thickness (mm) | Nominal O.D. (mm) | Weight* (kg/km) |

| 0.8 | 2 | 0.4 | 1.0 | 9.8 | 102 |

| 0.8 | 4 | 0.4 | 1.0 | 11.3 | 167 |

| 0.8 | 6 | 0.4 | 1.2 | 13.9 | 247 |

| 0.8 | 8 | 0.4 | 1.2 | 14.7 | 312 |

| 0.8 | 10 | 0.4 | 1.2 | 16.7 | 384 |

| 0.8 | 12 | 0.4 | 1.4 | 17.9 | 462 |

| 0.8 | 16 | 0.4 | 1.4 | 20.1 | 591 |

| 0.8 | 20 | 0.4 | 1.4 | 22.1 | 718 |

| 0.8 | 24 | 0.4 | 1.6 | 24.4 | 878 |

1.0 mm²

| Conductor Size (mm²) | No. of Pairs | Insulation Thickness (mm) | Outer Sheath Thickness (mm) | Nominal O.D. (mm) | Weight* (kg/km) |

| 1.0 | 2 | 0.4 | 1.0 | 10.2 | 114 |

| 1.0 | 4 | 0.4 | 1.0 | 11.7 | 189 |

| 1.0 | 6 | 0.4 | 1.2 | 14.4 | 281 |

| 1.0 | 8 | 0.4 | 1.2 | 15.3 | 355 |

| 1.0 | 10 | 0.4 | 1.2 | 17.4 | 439 |

| 1.0 | 12 | 0.4 | 1.4 | 18.6 | 527 |

| 1.0 | 16 | 0.4 | 1.4 | 21.0 | 677 |

| 1.0 | 20 | 0.4 | 1.6 | 23.5 | 846 |

| 1.0 | 24 | 0.4 | 1.6 | 25.5 | 1006 |

1.3 mm²

| Conductor Size (mm²) | No. of Pairs | Insulation Thickness (mm) | Outer Sheath Thickness (mm) | Nominal O.D. (mm) | Weight* (kg/km) |

| 1.3 | 2 | 0.4 | 1.0 | 11.5 | 131 |

| 1.3 | 4 | 0.4 | 1.2 | 13.8 | 234 |

| 1.3 | 6 | 0.4 | 1.2 | 16.5 | 330 |

| 1.3 | 8 | 0.4 | 1.2 | 17.6 | 420 |

| 1.3 | 10 | 0.4 | 1.4 | 20.4 | 537 |

| 1.3 | 12 | 0.4 | 1.4 | 21.3 | 624 |

| 1.3 | 16 | 0.4 | 1.4 | 24.1 | 804 |

| 1.3 | 20 | 0.4 | 1.6 | 27.1 | 1004 |

| 1.3 | 24 | 0.4 | 1.6 | 29.3 | 1196 |

1.5 mm²

| Conductor Size (mm²) | No. of Pairs | Insulation Thickness (mm) | Outer Sheath Thickness (mm) | Nominal O.D. (mm) | Weight* (kg/km) |

| 1.5 | 2 | 0.5 | 1.0 | 12.6 | 151 |

| 1.5 | 4 | 0.5 | 1.2 | 15.1 | 270 |

| 1.5 | 6 | 0.5 | 1.2 | 18.1 | 382 |

| 1.5 | 8 | 0.5 | 1.4 | 19.7 | 504 |

| 1.5 | 10 | 0.5 | 1.4 | 22.4 | 623 |

| 1.5 | 12 | 0.5 | 1.4 | 23.5 | 724 |

| 1.5 | 16 | 0.5 | 1.6 | 27.1 | 958 |

| 1.5 | 20 | 0.5 | 1.6 | 29.9 | 1168 |

| 1.5 | 24 | 0.5 | 1.6 | 32.8 | 1392 |

*The number here is just approx. weight. It changes according to the insulation material and the conductor used in different type of extension cable and compensating cable.