127/220kV XLPE Insulated, PE Sheathed High Voltage Power Cables

Application

These single core cables are designed for distribution of electrical power with nominal voltage 127/220kV. They are suitable for installation mostly in power supply stations, indoors and in cable ducts, outdoors, underground and in water as well as for installation on cable trays for industries, switchboards and power stations.

Standard

IEC 62067

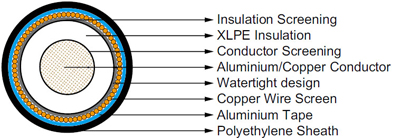

Construction

Conductor |

The cable conductors can be made of copper or aluminium, depending on customer’s preference or current carrying capacity. Large size solid conductors are made of aluminium. Available constructions including: round solid conductors up to 2000mm² (RE); circular stranded compacted conductors up to 1200mm² (RM); circular conductors with shaped wires up to 2000mm² (RM, Keystone conductors); segmental conductors up to 2500 mm² (RMS, Milliken conductors); oval shaped stranded compacted conductors up to 800mm² for external gas pressure cables (OM). |

Conductor Screen |

Extruded layer of semi-conducting cross-linkable compound is applied over the conductor and shall cover the surface completely. |

Insulation |

Insulation is of cross-linked polyethylene compound XLPE. |

Insulaton Screen |

Extruded layer of semi-conducting cross-linkable compound is applied over the insulation. |

Metallic Layer |

Copper wire screen. |

Moisture Barrier |

For radial moisture barrier a coated aluminium foil is longitudinally applied. The combination with the polyethlene oversheath is called aluminium polyethlene laminated (APL) sheath. This solution provides high short circuit capability and watertightness combined with lowest weight and smallest dimensions. For all XLPE insulated high voltage cables, the space between cable core and water barrier is made longitudinally watertight. |

Outer Sheath |

Extruded polyethylene. |

Dimensional Data

Nom. Cross-Section Area |

Nom. Insulation Thickness |

Copper Wire Screen Area |

Approx. Overall Diameter |

Approx. Weight |

|

CU |

AL |

||||

mm² |

mm |

mm² |

mm |

kg/m |

|

240 |

25.0 |

50 |

83.0 |

7.4 |

5.9 |

300 |

24.0 |

50 |

83.0 |

8.0 |

6.1 |

400 |

22.0 |

50 |

82.0 |

8.6 |

6.2 |

500 |

22.0 |

50 |

86.0 |

9.9 |

6.8 |

630 |

22.0 |

50 |

90.0 |

11.4 |

7.5 |

800 |

19.0 |

50 |

88.0 |

12.5 |

7.5 |

1000 |

19.0 |

110 |

98.0 |

16.0 |

10.0 |

1200 |

18.0 |

110 |

100.0 |

18.0 |

10.6 |

1400 |

18.0 |

110 |

103.0 |

20.0 |

11.4 |

1600 |

18.0 |

110 |

108.0 |

22.0 |

12.4 |

1800 |

19.0 |

110 |

113.0 |

25.0 |

13.6 |

2000 |

19.0 |

110 |

116.0 |

27.0 |

14.5 |

2500 |

19.0 |

110 |

123.0 |

32.0 |

16.6 |

Electrical Data

Nom. Cross-Section Area |

D C Resistance @20°C |

A C Resistance @90°C |

Capacitance per core |

Inductance |

Current Ratings/PowerRatings (continuous load) |

|||||

Cu conductor |

Al conductor |

|||||||||

Cu |

Al |

Cu |

Al |

1 circuit |

2 circuits |

1 circuit |

2 circuits |

|||

mm² |

Ω/km |

Ω/km |

Ω/km |

Ω/km |

μF/km |

mH/km |

A/MVA |

A/MVA |

||

|

|

|

|

|

|

|

trefoil installation |

|||

240 |

0.0754 |

0.125 |

0.0973 |

0.161 |

0.106 |

0.49 |

423/161 |

357/136 |

333/127 |

282/107 |

300 |

0.0601 |

0.100 |

0.0781 |

0.129 |

0.116 |

0.47 |

470/179 |

396/151 |

372/142 |

314/120 |

400 |

0.0470 |

0.0778 |

0.0618 |

0.101 |

0.133 |

0.44 |

524/200 |

440/168 |

420/160 |

352/134 |

500 |

0.0366 |

0.0605 |

0.0492 |

0.0791 |

0.143 |

0.42 |

584/223 |

489/186 |

473/180 |

396/151 |

630 |

0.0283 |

0.0469 |

0.0393 |

0.0622 |

0.155 |

0.41 |

648/247 |

540/206 |

531/202 |

443/169 |

800 |

0.0221 |

0.0367 |

0.0326 |

0.0500 |

0.187 |

0.38 |

702/267 |

582/222 |

587/224 |

487/186 |

|

|

|

|

|

|

|

flatinstallation |

|||

1000 |

0.0176 |

0.0291 |

0.0232 |

0.0375 |

0.215 |

0.56 |

989/377 |

857/327 |

782/298 |

678/258 |

1200 |

0.0151 |

0.0247 |

0.0201 |

0.0319 |

0.236 |

0.55 |

1060/404 |

917/349 |

849/324 |

734/280 |

1400 |

0.0129 |

0.0212 |

0.0175 |

0.0275 |

0.248 |

0.53 |

1136/433 |

981/374 |

915/349 |

790/301 |

1600 |

0.0113 |

0.0186 |

0.0156 |

0.0240 |

0.260 |

0.52 |

1201/458 |

1035/394 |

979/373 |

844/322 |

1800 |

0.0101 |

0.0165 |

0.0142 |

0.0213 |

0.260 |

0.51 |

1253/477 |

1080/412 |

1035/394 |

892/340 |

2000 |

0.0090 |

0.0149 |

0.0129 |

0.0193 |

0.270 |

0.50 |

1308/498 |

1126/429 |

1086/414 |

935/356 |

2500 |

0.0072 |

0.0119 |

0.0109 |

0.0156 |

0.294 |

0.47 |

1406/536 |

1207/460 |

1201/458 |

1031/393 |